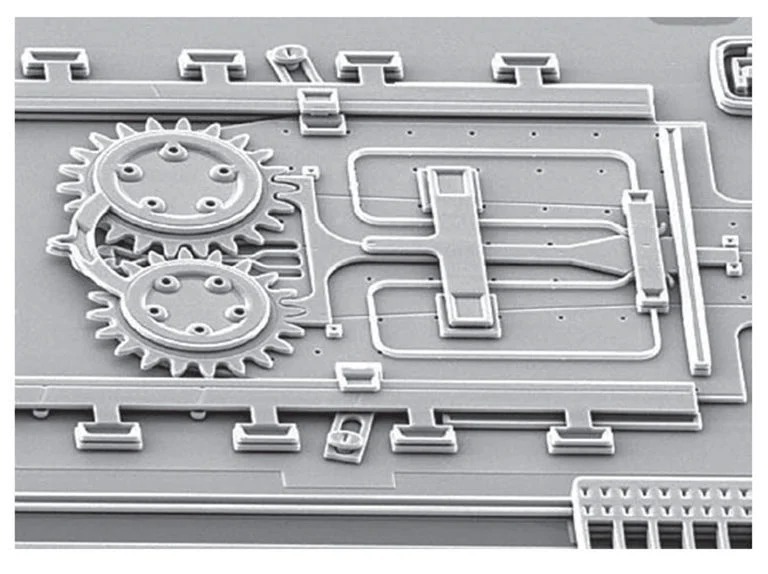

_ Department of systems (nano and microelectric and mechanical MEMS )

systems (nano and microelectric and mechanical MEMS ) and manufacturing of nanoelectronic tools and devices

Researcher and author: Dr. ( Afshin Rashid)

Note: To reproduce and build systems (nano and microelectrical and mechanical MEMS ), we apply a set of techniques using a solution of nanoparticles, which we create a very thin layer on the desired substrate, and as a layer The intermediate is used during the nanopatterning process.

To reproduce and build systems (nano and microelectricaland mechanical MEMS) according to the interaction between nanoparticles, they can organize themselves and create a thin layer that creates a hole between them, this technique was initially lithography It was called natural . Due to the integral nature of colloidal particles and their hydrophilic character, they form a colloidal crystal with ordered cavities through which the substances of interest penetrate and deposit on the substrate. For example, polystyrene latex nanospheres can be used. Materials deposited on nanoparticles disappear after immersing the sample in a suitable solvent and sonication. This process in the reproduction and construction of systems (nano and microelectricand mechanical MEMS) شبیه یک فرآیند برداشتن است . از مزایای این تکنیک می توان به الگوهای وسیع ، سادگی ، وضوح خوب و قابلیت ترکیب با سایر تکنیک ها برای تکثیر و ساخت سیستم های (نانو و میکرو اِلکترومکانیکال MEMS) اشاره کرد. از سوی دیگر ، این تکنیک با توجه به اشکال محدود موجود برای مواد کاربردی الگو دار ، ترتیب برد نانو الگوها و وجود نقص نقطه ای ، مشکلاتی را ایجاد می کند.

In general, if two techniques for replicating and manufacturing systems (nano and microelectricand mechanical MEMS) can complement each other in terms of resolution or pattern area, it is logical to combine them in a single device. This approach has been used to fabricate single-electron transistors, integrating direct laser writing for large-area exposures and thermal probe lithography for high-resolution patterns , combining (nano- and micro -electromechanical MEMS)systems using It is a composite nanolithography resist layer , created in a mix-and-match process. In this sense, it usually requires the successive use of the technique of reproduction and construction of systems (nano and microelectricومکانیکال MEMS) با مساحت وسیع برای الگوی ابعاد غیر بحرانی و تکنیک لیتوگرافی با وضوح بالا برای الگوبرداری از کوچکترین ابعاد ، با پروتکل های مناسب برای تراز سیستم های (نانو و میکرو اِلکترومکانیکال MEMS) است. برای تکثیر و ساخت سیستم های (نانو و میکرو اِلکترومکانیکال MEMS) همچنین برای انجام قرار گرفتن در معرض مقاومت پی در پی مقاومت های شیمیایی تقویت شده توسط لیتوگرافی نوری و لیتوگرافی پرتو الکترونی استفاده شده است برای تکثیر و ساخت سیستم های (نانو و میکرو اِلکترومکانیکال MEMS) از لیتوگرافی از بالا به پایین و خود سازماندهی دو پلیمر را از پایین به بالا به منظور تولید نانو الگوی با وضوح بالا در مناطق بزرگ است. Typically, the self-organization of block copolymers is randomly oriented and lacks long-range order , but the previous top-down pattern provides a substrate for the replication and fabrication of (nano- and micro -electromechanical MEMS)systems, systems (nano- and micro-electromechanical MEMS) of a substrate cause the preferential growth of semiconductor materials in the irradiated regions, which can be used to fabricate ordered arrays of semiconductor dots.

Conclusion :

To reproduce and build systems (nano and microelectrical and mechanical MEMS ), we use a set of techniques using a solution of nanoparticles, which we create a very thin layer on the desired substrate, and as an intermediate layer in The length of the nanopattern process is used.

Researcher and author: Dr. ( Afshin Rashid)