Section _ reproduction and production of nanowires

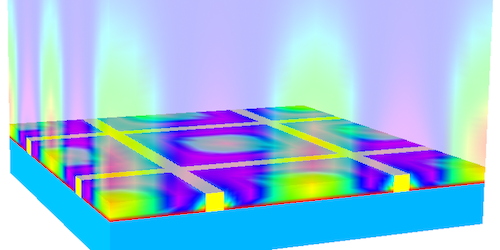

The use of nano photoelectric process in the production of electronic nanowires

Researcher and author: Dr. ( Afshin Rashid)

Note: The advantages of SiNWs in the use and development of sensor operating systems are due to the well-known properties of silicon and its favorable manufacturing processes. Among the physical properties of these nanowires, we can mention their electrical, photoelectric and mechanical properties.

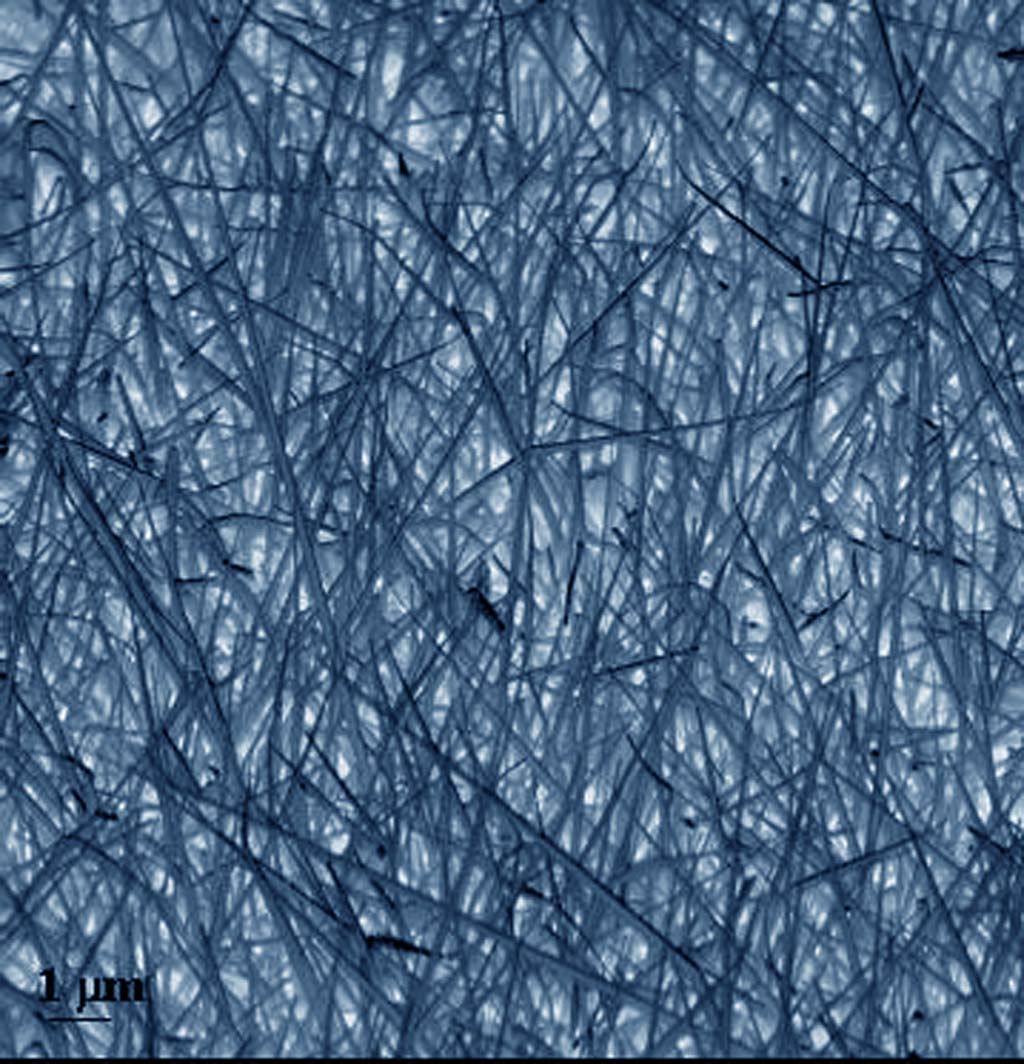

Silicon nanowires are one of the best examples of semiconductor nanostructures that can be made as a single crystal with a diameter of 9 to 0 nm. Nanowires ( SiNWs) have high mobility and surface-to-volume ratio, which makes them easy to control using a weak electric field. These one-dimensional nanostructures are created from nanowires with a diameter in the range of nanometers and a length of more than a micrometer. In the manufacture of nanowires through regular one-dimensional arrays, it has been done with the help of different physical and chemical methods.

Methods such as the use of electron beam or lithography method, heavy ion irradiation, laser, chemical and electrochemical methods such as water heat and spontaneous assembly methods used to make the membranes of molds can also be used . In the manufacturing of one-dimensional nanostructures such as nanowires by the electro-accumulation method, there are three general steps: firstly, the creation of a porous mold as a suitable substrate and framework for the accumulation of nanowires, secondly, the growth of nanowires in line with the holes of the mold, and thirdly, removal The mold and the separation of nanowires are from it. The properties of nanowires are directly dependent on the surface characteristics of the mold such as the size distribution of the holes, the density of the holes and the superiority of the surface of the nanoholes. In order to control the characteristics of nanowires, the parameters that are effective in the formation and optimization of the diameter of the holes and the thickness of the mold should be considered.

Conclusion:

Magnetic nanowires such as cobalt, nickel, iron and alloys can be made by electroaccumulation and spontaneous accumulation on an anodic aluminum oxide template, and the magnetic properties of cobalt nanowire arrays such as coercive force, saturation electromagnetism and residual magnetization are related to the configuration of nanowires. and the diameter of the nanowires depends. This characteristic of nanowires can be easily controlled by changing the influencing factors in mold making, such as the potential of the oxidation process and pH. He pointed out applications in chemical nano sensors, logical nano tools and other nano electronic and nano optical tools.

Researcher and author: Dr. ( Afshin Rashid)

Specialized doctorate in nano-microelectronics