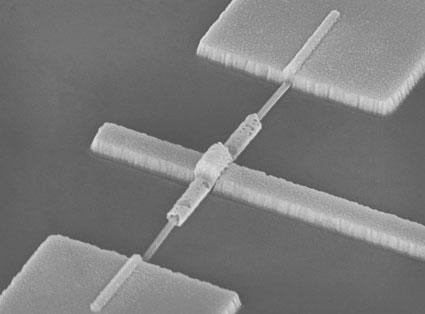

In the circuit diagram of one (nano-transistor) the effect of a multilayer Si graphene field, the two source and drain electrodes are directly connected to the semiconductor (PhD Nano-Microelectronics)

Researcher and author: Dr. ( Afshin Rashid)

Note: Graphene, which consists of only one carbon atom, can be used to make multilayer graphene field effect nanotransistors that consume less energy and take up less space.

Graphene is a semiconductor material with zero gap and unsuitable for logic circuits, but using nanotechnology, they create different forms of this material that have different gaps. Graphene nanofibers, multilayer graphenes, and graphene grown on Si are such forms. The term nano-transistor comes from the combination of the term nano-scale in transmission and resistance. In a graphene Si field effect nanotransistor, the resistance between two electrodes can be transmitted or controlled by a third electrode. In a multi-layer Si graphene field effect nanotransistor, the current between the two electrodes is controlled by an electric field from the third electrode. In contrast, the bipolar transistor is capacitively connected to the third electrode and is not in contact with the semiconductor. Three electrodes are connected to the source, drain and gate in the structure of the Si multilayer graphene field effect nanotransistor.

In the circuit diagram of a multilayer Si graphene field nanotransistor, the two source and drain electrodes are connected directly to the semiconductor, while the gate electrode is capacitively connected to the semiconductor using a gate dielectric. The electric field generated by the gate electrode controls the current generated by the two source and drain electrodes. The drain current is modulated by changing the density of the charge carriers in the two-dimensional transmission channel. In the nanotransistor, the effect of a multi-layer Si graphene field is modulated by a three-dimensional transmission channel with a three-dimensional transmission channel thickness. Numerous chemical and physical methods have been proposed for the production of various types of multilayer nano-graphene. The basis of the work of physical methods is that in these methods try, the forces between the graphene plates in Remove the graphite and separate them to form graphene or graphene oxide monolayers, which is the same top- down method. In chemical methods, multilayer nano-graphene is made by putting each carbon atom together, which is also called the bottom-up method. In the multi-layer nano-graphene peeling method, the electronic quality of the layers is high, the cost of producing graphene in this method is low and does not require special equipment. In field effect nanotransistors using graphene (Si), the number of nanographene layers produced by this method is single and multilayer. One of the limitations of using this method is that it is not suitable for bulk production and the thin layers produced are non-uniform and uneven and it is a time consuming method.