A combination of interfering nano-lithography and nanoelectronic lithography makes it possible to fabricate and reproduce high-resolution structures over large areas (PhD in Nano-Microelectronics)

Researcher and author: Dr. ( Afshin Rashid)

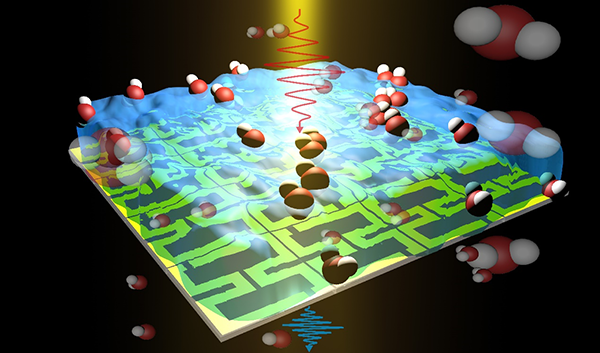

Note: Micro and nanostructures can be used to reduce the reflection or conduction of light in applications such as photovoltaic solar cells, LEDs, or nanoelectronics technology.

Electron beam lithography allows precise control of nanostructured properties that form the basis of various nanotechnologies. The nanostructure fabrication and measurement team promotes lithographic accuracy at the nanometer scale and creates processes for building innovative devices and standards in the physical fields from photons to fluids. Electron beam nano-lithography allows precise control of the nanostructured features that form the basis of various device technologies. Lateral resolution of 10 nm, placement accuracy of 1 nm and modeling fields of 1 mm are all possible. However, the achievement of these performance criteria depends on the interdependent factors that are specific to the sample - pattern definition and failure, substrate and mask materials, pre-exposure and post-exposure processes, alignment feature definition - And also, importantly, the details of the operation of the lithography system. As a core capability, and develop processes that are within or near the range of conventional electron beam lithography to advance nanoscale devices and measurement science in various fields, such as chip-scale frequency combs to save time. Accurate. Integrated nonlinear optics for wavelength and quantum frequency conversion. And on-cavity mechanical and micro / nano-electromechanical optical systems for studies of measurement, transmission and nonlinear dynamics; Integrated quantum photon circuits with nonlinear and quantum light sources for quantum information. Ultraviolet to infrared surfaces for trapping and exploring atoms and ions, polarization, imaging and shaping ultra-fast space-time laser pulses. Optical microscope standards for correcting aberrations and advancing essential capabilities in electron beam lithography, and developing methods for better control, measurement, and understanding of fabrication processes. To reduce the barrier to electron beam lithography and improve pattern accuracy control, the nanolithography toolbox is also used. To improve pattern placement, electron beam lithography is used for pattern standards for atomic force correlation microscopy and high-resolution optical microscopy, with local Accurate optimization with high throughput and characterization and optimization of process parameters. Such measurements provide a positive feedback loop for the fabrication and measurement of nanostructures.

The ability to produce large microstructures and nanostructures on non-planar surfaces is important for many applications such as optics, optoelectronics, nanophotonics, imaging technology, NEMS and microfluids. However, it is very difficult to create large nanostructures on curved or non-planar surfaces using existing modeling methods. In addition, current types of nanotechnology technologies such as electron beam lithography, optical lithography, interference lithography (IL), etc., can not meet all the application demands of industrial applications in terms of high resolution, high power, low cost. , Large area and olgoes on uneven and curved surface. Therefore, new high-volume nanotechnology technology is in dire need of exploitation and development to meet the tremendous needs of emerging markets. Nanoelectronic lithography is currently considered as a promising low-cost, high-power, high-resolution nano-pattern method, especially for the production of small-scale / large-scale nano-patterns and complex 3D structures. The above aspects have also created proportional features due to these salient advantages. The conversion of optical structures in combination with the construction of a large area becomes a more effective method in this field. In particular, nanoelectronic lithography has great potential for setting new benchmarks for the construction of miniature, low-cost, low-weight optics that can be used in many applications.

Conclusion :

Micro and nanostructures can be used to reduce the reflection or conduction of light in applications such as photovoltaic solar cells, LEDs, or nanoelectronics technology.

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics