Department of systems (nano and microelectric and mechanical MEMS )

Step 3 (in exposing the photolithography and its development : (photolithography Exposure, and Development)

Researcher and author: Dr. ( Afshin Rashid)

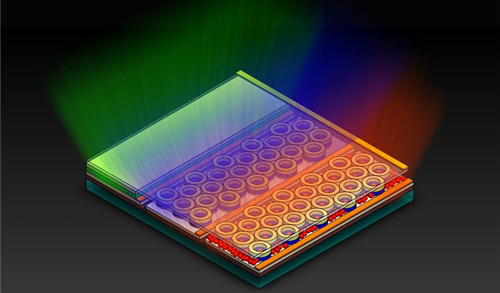

Note: In the preparation and manufacturing of systems (nano, micro-electric and mechanical MEMS ) , the photoresist is exposed to ultraviolet light like an optical engraving mask (optical mask). This optical mask blocks the light path and defines a pattern to ensure optimal surface mapping .

In the structure of (nano and microelectric and mechanical MEMS ) systems, optical masks are usually made using fused silica and optical transparency that are exposed to the effective wavelength, width and thermal expansion . A cloudy layer is placed on a glass or (quartz) surface as a sample. ( Usually a chrome layer with a thickness of hundreds of angstroms). An optical mask is produced based on the required shape of polysilicon shell . The mapping of the surface is determined by the mask. Photoresistor is then created. In the structure of (nano and microelectric and mechanical MEMS ) systems, a positive photoresistor, light, It reduces the molecular weight of the optical resistance and selectively removes the material with the lowest molecular weight that causes the optical resistance.

In the preparation and construction of systems (nano and microelectrical and mechanical MEMS ), the optimization of the architecture of multi-element optical circuits and traditional technologies is possible by using the unique optical behavior of nano-optics. Bandi obtained one from the other to create overall optical effects. Spatial integration can be achieved by organizing different optical functions into an array structure through repeating nanopatterns. Composite integration is achieved by adding a nano-optical layer(s) to functional optical materials.

Examining the band gap structure of nanoelectronics devices and systems (nano, microelectric and mechanical MEMS ) , in addition to introducing a method for researching the performance of one-dimensional systems, has made it possible to improve the electrical-optical properties of electronic components. Devices based on organic materials can be mechanically flexible to a large extent due to the loose intermolecular bonds in the nanoelectrons created from them . Unlike these organic materials, inorganic materials such as silicon, germanium, and gallium arsenide can be used in the structure of electronic devices, especially (nano and microelectrical and mechanical MEMS ) systems only in crystalline states, and in this case, covalent bonds provide flexibility. They make it impossible. properties Such as strength, flexibility, electrical conductivity, magnetic properties, color, reactivity, etc. Starting to change the properties of the material by shrinking it depends above all on the type of material and the desired property. For example, with the reduction of the dimensions of a nanomaterial in the construction of (nano and microelectrical and mechanical MEMS ) systems , generally some mechanical properties of materials such as strength are improved. This increase in strength does not happen only in the range of a few nanometers, and the strength of materials of several tens or even hundreds of nanometers may be much higher than the mass material of a large scale. On the other hand, the change of some properties such as color and magnetic properties may occur in dimensions of only a few nanometers. In addition to these two items, the state of the energy levels of the electrons around each atom, as well as the number of electrons in the layer The last one is also effective in determining the properties of that atom or substance. This feature can play a decisive role in the mechanism of combining chemical properties of that material in the construction and preparation of systems (nano, micro-electric and mechanical MEMS ) . For example, the properties of a metal ion are different from the metal atom. Until now, the role of three factors, atomic number, mass number and electronic arrangement of the material is effective in determining the properties of the electrons of the nanostructure of the material. Macroscopic properties of a substance such as melting point, boiling point and electrical conductivity, through the study of a sample that is sufficient to measure in the usual conditions of nanoparticles. This is not true for all materials, when the material size is reduced and reaches nanometer dimensions, behavior and properties are possible completely different from the same material in large dimensions. If a substance with a band gap structure of nanoelectronic devices and systems (nano, microelectric and mechanical MEMS ) with a scale of several tens of meters is reduced to millimeter dimensions, there will be no change in its melting point, color and magnetic properties. But this change can be seen when reducing the material to nanometer dimensions, and the number of surface atoms in materials with scales larger than nanometers is very small, but upon entering the nanometer world, the amount of these atoms increases greatly compared to the total atoms of the material.

Conclusion :

In the preparation and construction of systems (nano and microelectrical and mechanical MEMS ), the photoresist is exposed to ultraviolet light like an optical engraving mask (optical mask). This optical mask blocks the light path and defines a pattern to ensure optimal surface mapping .

Researcher and author: Dr. ( Afshin Rashid)

Specialized doctorate in nano-microelectronics