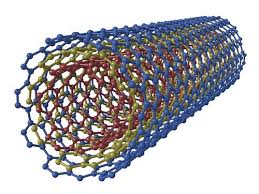

Reproduction of CNTs electronic nanotubes by CVD method (based on nano-micro-electronics PHD ) (educational-research doctorate)

Researcher and author: PhD student Afshin Rashid

Note: Carbon nanotubes are manufactured and reproduced using a variety of methods , such as CVD, laser irradiation, and hardening . CVD is the best option for industrial production of carbon nanotubes. The reason for this is the low cost-to-income ratio and the possibility of vertical growth of nanotubes on the desired substrate .

In this process, the carbon in the negative electrode is submerged, which is due to the high temperature in the discharge process. Since this method was first used to synthesize nanotubes , it is known as the most common method of producing carbon nanotubes. In this method, which consists of both nanotubes, single-walled and multi-walled, with lengths up to 50 microns containing structural defects. In the process of laser radiation, the laser is used to evaporate the graphite and an inert gas is used to direct these vapors into the tank. Carbon nanotubes grow on the cold surface of the reactor . This is suitable for the production of multi-walled carbon nanotubes. And with The use of graphite composite and fossil catalyst particles using a combination of cobalt and nickel (for the synthesis of carbon nanotubes) CNT and CNTs is used. The efficiency of this process is 70 % and its main product is single-walled and multi-walled carbon nanotubes. The diameter of these nanotubes can be completely controlled and the diameter of the nanotube can be arbitrarily controlled by changing the temperature .

The CVD method uses catalysts to produce carbon nanotubes . Throughout the CVD process, a layer of nickel, cobalt, and metal catalyst particles is generally used to produce carbon nanotubes . CVD is a common method for commercial production of carbon nanotubes. In this method, the diameter of the nanotubes is related to the dimensions of the metal particles. By underlaying the substrate, using heat treatment and catalyzing the catalytic refining, the diameter of the nanotubes can be controlled.

Conclusion:

If carbon nanotubes are used to grow a strong electric field, nanotubes will grow at the top of the applied field . CVD is the best option for industrial production of carbon nanotubes. The reason for this is the low cost-to-income ratio as well as the possibility of vertical growth of nanotubes on the desired substrate .

Author: PhD Student ( Afshin Rashid)