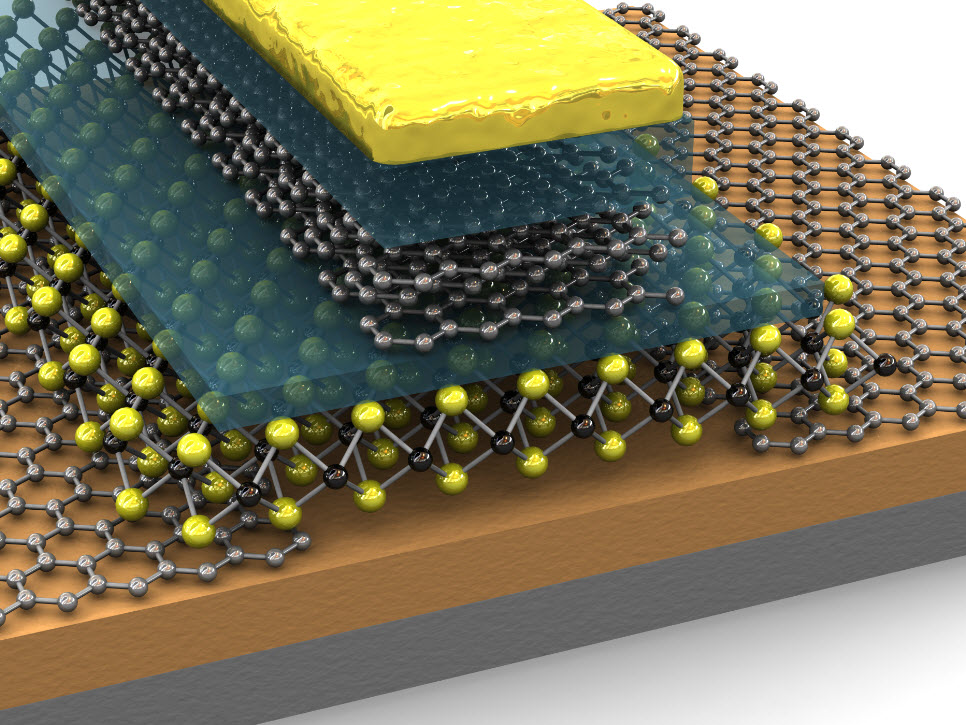

_ Section of the simulation process in (electrical nanoparticles)

(characteristics) or Nanoparticle methodology in the production or simulation of nanoparticles

Researcher and author: Dr. ( Afshin Rashid)

Note: Many methods have been developed to produce nanoparticles or nanostructured particles, which include vapor, liquid and solid state processes.

In general, chemical reactions to produce nanoparticles can take place in any of the solid, liquid, and gas states. The common method is to produce materials in a solid state, by crushing the particles, their contact surface is increased, and further, to increase the penetration of atoms and ions, this mixture is increased at high temperatures. In chemistry, the substances with which chemical reactions begin are called reactants, and the substances that are transformed into them during the reaction (reactants) are called products. Reactants can be solid, liquid or gas. In addition, reactants or They are an independent element or they can be multi-component compounds. Multicomponent compounds are usually called precursors.

To produce nano particles with the help of nano technology, changes can be made in atoms by controlling their properties. When materials are studied and investigated at the nano scale, the reactions and behavior of atoms are completely different compared to the case where the study is carried out at the molecular level, because in this realm the physical properties of materials change, it is just like being in a ball. drop it in a compartment and take out another ball from that compartment. The difference in the nano realm is so great that even the color, melting point, chemical properties, etc. of materials outside this range are completely different.

In nanotechnology, two methods are considered for manufacturing: bottom-up manufacturing method and top-down manufacturing method. In the bottom-up construction method, devices and materials are built from the molecular level based on the principles of molecular chemistry, just like a wall is built from brick by brick. In the top-down manufacturing method, nano objects are made in larger quantities without atomic control, in this way, advanced equipment of this technology, such as atomic microscopes and scanning tunneling microscopes, are used in their manufacture to manipulate the process and create new phenomena and properties. appear in nano objects. One of the important properties of nanoparticles is the high surface to volume ratio of these materials. Using this property, powerful catalysts can be produced in nanometer dimensions. These nanocatalysts will greatly increase the efficiency of chemical reactions and also significantly prevent the production of waste materials in reactions.

The use of nanoparticles in the production of other materials can increase their strength or reduce their weight, increase their chemical and thermal resistance , and change their reaction to light and other radiations. So, the first application that can be imagined for nanoparticles is The use of these materials is in the production of nanocomposites. By using nanoparticles, the strength-to-weight ratio of composite materials will be greatly increased.