Optical Nanoelectro Lithography Using Resistors (PhD _ Nano _ Microelectronics)

Researcher and author: Dr. ( Afshin Rashid)

Note: Nano-lithography includes a set of top-down fabrication techniques that enable the modeling of materials and the fabrication of nanoscale-resolution devices. Nano-lithography is complemented by thin film deposition techniques as well as self-assembly and self-organization to offer a wide variety of nanostructured strategies.

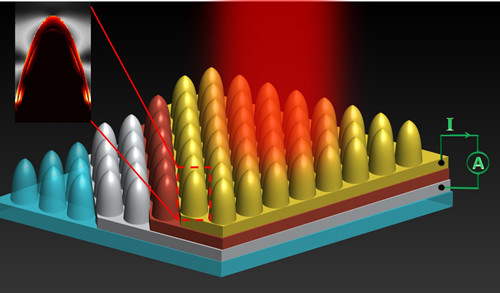

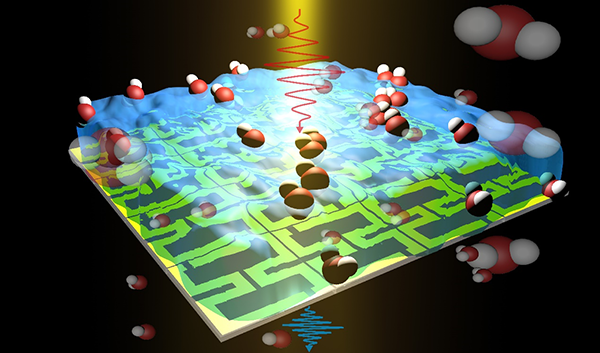

Key concepts of nano-lithography infrastructure is one of the main points in nanoelectronics and the main techniques of nano-lithography are introduced and in terms of achievable clarity, operational power, pattern complexity, process complexity and cost, one of the most practical subsets of nano and nano sciences Electronics are categorized. The main applications of nano-lithography with emphasis on the overwhelming role of nano-lithography in the semiconductor industry, in nanotechnology and in new applications. In general, top-down approaches are used using thin film deposition techniques (spraying, molecular beam epitaxy, pulsed laser deposition, chemical vapor deposition, thermal evaporation, electrode expansion, etc.) and nano-lithographic techniques. Two approaches are usually followed. In the first method, a thin film (or multilayer film) is grown on a substrate, with precise control of the layer thickness. Depending on the homogeneity of the growing method and the growing equipment used, this area of the substrate can reach large values in the range of tens of centimeters, or beyond. In the second step, a lithographic method is used to model the film to the micrometer or nanometer side dimensions and remove the material in certain places. In the nano-lithography stage, it is first performed on a bare bed, after which the growth of the material increases. This is the so-called lifting technique . A combination of both approaches is often required in multi-step processes to build complex devices.

One of the most important parameters of nanoscale lithography maximum resolution achievable is to However, the resolution will change if the desired pattern is dense or features are separate. In general, any nano-lithography method suffers from the effects of proximity and requires specific strategies for dense patterns. Traditionally, the sharpness of the nano-lithography technique is defined as the minimum achievable distance between two isolated or dissolved features. However, segregation is sometimes considered as the minimum lateral dimension of an isolated feature made by the relevant nanolithographic technique. It is usually used to express smaller features that can be made. In later chapters, the specific limitations of each technique to achieve better clarity In some cases, due to practical limitations, the nano-electro-lithography method can not be used to make nano-electronic devices. It is obvious that these restrictions could be one of the equipment or the cost of the process is . For example, optical lithography is now able to construct structures in the range of 10 nanometers.

Conclusion :

Nano-lithography includes a set of top-down fabrication techniques that enable the modeling of materials and the fabrication of nanoscale-resolution devices. Nano-lithography is complemented by thin film deposition techniques as well as self-assembly and self-organization to offer a wide variety of nanostructured strategies.

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics