CarbonNano_Fiber or CNF (Structure and Applications) PhD Nano _ Microelectronics

Researcher and author: Dr. ( Afshin Rashid)

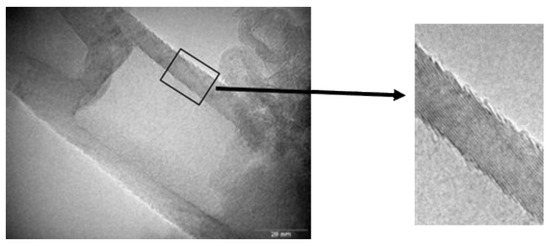

Note: Characteristics and applications of carbon nanofibers (CNF) synthesized using VGCF technology. - Vapor carbon nanofibers grown in a group of materials called multilayer carbon nanotubes (MWCNT) and are produced using the floating catalyst method.

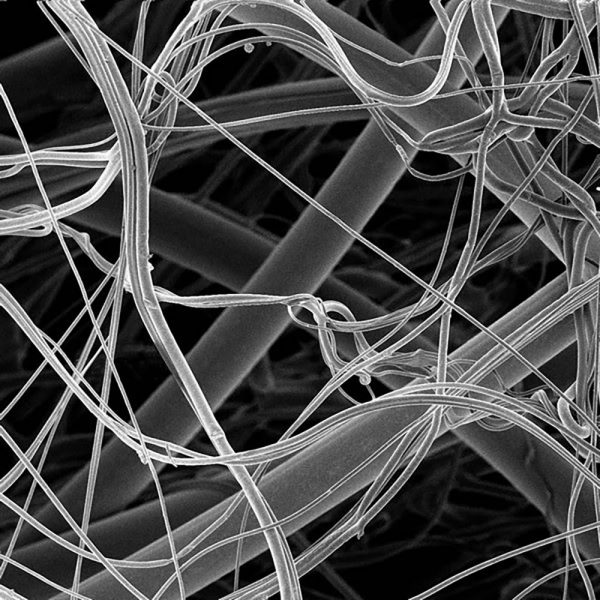

Discrete carbon fiber (CNF) is a discrete, highly graphite, highly compatible with most polymer processing techniques and can be dispersed in isotropic or anisotropic states. CNFs have excellent mechanical properties, high electrical conductivity and high thermal conductivity that can be transferred to a wide range of matrices including thermoplastics, thermostats, elastomers, ceramics and metals. Carbon nanofibers also have a unique surface finish, which facilitates performance and other surface modification techniques for setting and engineering nanofibers to the host polymer or its application.

The average diameters of the carbon nanotubes offered range from 125 to 150 nanometers, depending on their grade and length from 50 to 100 micrometers. These nanofibers are much smaller in diameter than continuous or milled carbon fibers (5-10 nm) and are significantly larger than carbon nanotubes (1-20 nm), yet have many similar advantages. Carbon nanofibers are refined after production to transfer various properties to the surface. There are generally three types of nanofibers. pyrotically simple to remove surface hydrocarbons and produce a virgin surface for chemical bonding. This type of nanofiber also serves as a precursor to the other two lists. To provide the best combination of mechanical and electrical properties, it is thermally placed at a temperature of 1500 ° C, while For the production of products without catalysts and to maximize the thermal conductivity properties in composites, it reaches a temperature of 2900 ° C.

Nanofibers) Nanofiber is a term that refers to fibers with diameters less than 500 nanometers. When the diameter of polymer fibers is reduced from a micron to a few hundred nanometers, they can achieve amazing properties such as a very high surface-to-volume ratio - good flexibility and high mechanical performance. The main property of fibers is a very high ratio of length to diameter. Micron fibers are fibers in which filaments of less than one denier in mass per unit of heat per 9,000 meters less than one micrometer are called nanofibers . These fibers with relatively short lengths of several microns and a diameter of less than 500 nanometers, like nanowires, are a variety of one-dimensional structures. In general, there are several methods for the production of nanofibers, some of which include the method of stretching, separation of multi-component fibers, mold method, blowing, fuzzy separation, self-decoration Macromolecules, electrolysis and so on. Risna produces polymer fibers with a diameter below nanometers.