Comparison of key parameters of nanoparticles of field effect based on carbon nanotubes with bulk MOSFET and UTS MOSFET (based on nanotechnology - microelectronics PHD)

Researcher and author PhD student : Afshin Rashid

Note: All nano-transistors on a wafer are turned on and off at the same time because they have the same gate. Low voltage parts cause problems.

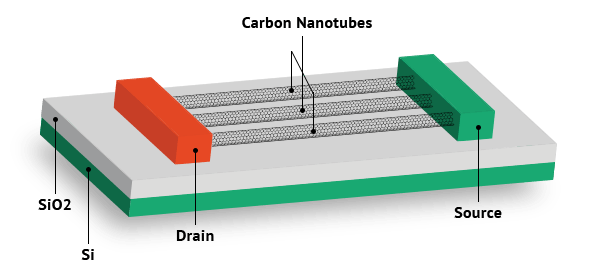

In the structure of high gate nanotransistors, for more benefit, carbon nanotubes are completely placed inside the gate insulation. Unlike transistors, the effect of the back gate carbon nanotube field, a large number of this type of transistor can be made on a wafer. , Because the gates of each are separate. Also, due to the low dielectric thickness of the gate in the nano-transistor, a larger electric field can be created with a low voltage on the carbon nanotube. Despite the more sophisticated manufacturing process than the rear gate nanotube field effect transistors, the above advantages make this type preferred.

Place the gate around and in all the nanotubes that improve performance. First, the carbon nanotube, which has an insulating coating, is placed on the wafer, where the metal connection of the source and the drain is placed on both sides, then to mark and Separating the source area and drain, si is added under the carbon nanotube. This decontamination continues until the bed is insulated. Then, using materials with a high dielectric coefficient, insulation is created between the gate and the source and drain, and also metal is placed on this insulation to better connect the gate metal to the carbon nanotube.

Conclusion:

The process of making nanotubes has caused variability in the diameter of the tubes, which usually has a value between 1 and 2 nanometers. By changing the diameter of the nanotube, the band gap changes and as a result, the voltage across the transistor and the current of the transistor changes.

Author: PhD Student ( Afshin Rashid)