خاصیت ابر رسانایی Nanoparticles و دیامغناطیسی در ساختار نانو سیم ها (برق _ الکترونیک) دکترای آموزشی _ پژوهشی

نویسنده و پژوهشگر: دکتر ( افشین رشید)

نکته: نانو سیم های سیلیکونی یکی از بهترین مثالها برای نانو ساختارهای نیمه هادی هستند که می توانند به صورت تک بلور با قطر کوچک به اندازه 9 تا 0 نانومتر ساخته شوند.

ماهیت الکترومغناطیسى نانو ذرات در مواد مغناطیسى، مولکولها و اتم هاى سازنده ى آن خاصیت الکترومغناطیسى دارند. به بیان ساده تر عناصرى مانند آهن، کبالت، نیکل و آلیاژهاى آنها که توسط آهنربا جذب میگردد. مواد مغناطیسى نامیده میشود.طبقه بندى مواد الکترو مغناطیسى بر اساس پذیرفتارى مغناطیسى (قابلیت مغناطیسى شدن ماده ) انجام میشود. بر این اساس مواد را به سه گروه فرومغناطیس، پارامغناطیس و دیامغناطیس دسته بندى میکنند. برایند گشتاور دو قطبى در مواد دیامغناطیس الکترومغناطیسى صفر است و در حضور میدان مغناطیسى، گشتاور دو قطبى در آنها القا میشود؛ اما جهت این دو قطبى هاى القا شده برخلاف جهت میدان مغناطیسى خارجى است که باعث میشود ماده ى (دیامغناطیس) از میدان مغناطیسى دفع شود. با حذف میدان مغناطیسى خارجى، خاصیت مغناطیسى این مواد باقى نمیماند. پذیرفتارى مغناطیسى این مواد منفى و خیلى کم (در حدود 6-10 -تا 3-10 ) میباشد. تمام گازها (جز اکسیژن) ، آب، نقره، طلا، مس ، الماس ، گرافیت ، بیسموت و بسیارى از ترکیب هاى آلى (دیامغناطیس) هستند. دو قطبى هاى مغناطیسى در ماده ى پارامغناطیس، داراى سمتگیرى مشخص و منظمى نیستند؛ در نتیجه این مواد خاصیت مغناطیسى ندارند. اگر آنها درون یک میدان مغناطیسى قرار داده شوند، در راستاى خط هاى میدان مغناطیسى منظم میشوند. با حذف میدان مغناطیسى، دوقطبى هاى مغناطیسى دوباره به سرعت به وضعیت قبلى که در غیاب میدان داشتند، بر میگردند. به این ترتیب، مواد پارامغناطیس در میدانهاى نانو الکترو مغناطیسى قوى خاصیت مغناطیسى پیدا میکنند.

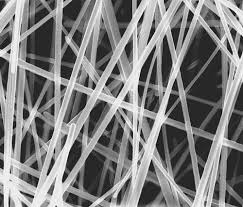

نانو سیم ها nano wire دارای ساختاری که از نسبت طول به عرضِ شگفت انگیز برخوردارند. نانو سیم ها بسیار نازک هستند - ایجاد نانو سیمی با قطر فقط یک نانومتر امکان پذیر است، از نانو سیم ها برای ایجاد کوچکترین ترانزیستور (نانو ترانزیستور ها) استفاده میشود. نانو سیم Nano wire می تواند خواص عایق ،نیمه هادی یا فلز را داشته باشد. عایق ها بار الکتریکی را تحمل نمی کنند ، در حالی که فلزات بارهای الکتریکی بسیار خوبی دارند. نیمه هادی ها بین این دو قرار دارند و تحت شرایط مناسب شارژ می شوند. با قرار دادن سیم های نیمه هادی در پیکربندی مناسب می توان ترانزیستور هایی ساخت که یا به عنوان سوئیچ یا تقویت کننده عمل می کند .برخی از ویژگی های جالب و ضد انعطاف پذیر نانو سیم ها به دلیل مقیاس کوچک است.

نتیجه گیری:

نانو سیمها دقیقاً مانند سیمهای معمولی الکتریکی غیر از این واقعیت هستند که بسیار کوچک هستند. مانند سیم های معمولی ، نانو سیم ها را می توان از انواع مواد رسانا و نیمه رسانا مانند مس ، نقره ، طلا ، آهن ، سیلیکون ، اکسید روی و ژرمانیوم ساخت. نانو سیم ها همچنین می توانند از نانو لوله های کربن ساخته شوند.

نویسنده و پژوهشگر: دکتر ( افشین رشید)