Nano ESD electrostatic nanoparticles in the structure of nano-devices (PhD in Nano-Microelectronics)

Researcher and author: Dr. ( Afshin Rashid)

Note: Electrostatic ESD semiconductor nanoparticles were fabricated using an electro-spray process. Electro-spray deposition (ESD) method is one of the steps of preparing particles from the spray gas production path. The ESD method, which produces nanoparticle droplets, together with the evaporation of nanoparticle solvent can produce a nanoparticle whose size is controlled to the size of the nanoscale and create a quantum confinement effect.

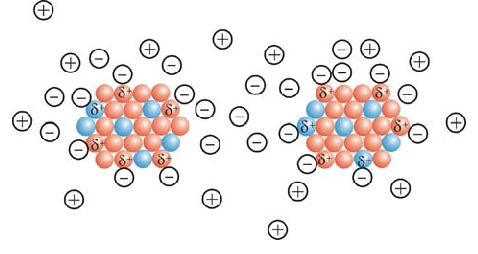

Nanoparticle surface atoms are not energy compensated. In general, the growth results of nanoparticle energy can be expressed as the total energy of the surface atoms of the particle. The freedom of movement of atoms on the surface of nanostructures is limited, and only vibrational movements and the movement of electrons are possible. These two electro-kinetic reactions are interdependent because the displacement of the electron clouds of the atoms inevitably changes the vibrational frequencies of the bonds of the nanoparticle atoms . On the other hand, the displacement of capacitance electrons in bonds changes the polarity of bonds and bodies called supermolecules . In this case, electron transfer to a higher energy level is possible.

Metal alloys or bimetallic nanoparticles have high electrostatic ESD properties, making them suitable for electromagnetic nanomolecules or nanoelectromagnetic carriers . In addition, the electromagnetic properties of the surface of these nanoparticles allow surfactants to be placed on the surface of their nanoparticles that can be used to dissolve the nanoparticles . Surface coating is an integral part of electromagnetic nanoparticles that can be used. Although nanoparticles are not attracted to each other due to their paramagnetic supercharger properties , due to the high energy of the surfaces, electromagnetic nanoparticles tend to accumulate and accumulate. Nanomolecular electrostatic stability for Nanoparticles are not suitable; Although the repulsion of charges on the surface of nanoparticles can prevent their accumulation, in the presence of a catalyst or other electrolytes in the internal environment of ESD electrostatic nanoparticles, these charges are neutralized. The electromagnetic properties of the nanoparticles in the coating, like a barrier, prevent them from accumulating, and the chemical functionalization provides suitable and efficient properties for the nanoparticles . Molecular weight and geometric orientation exist on the surface of nanoparticles in various forms. Layers that fully activate electromagnetic nanoparticles. Prevents nanoparticles from accumulating on top of each other. In addition to organic coatings, the core-shell structure is also used for optimal use of electromagnetic nanoparticles .

Conclusion:

Electrostatic ESD semiconductor nanoparticles were fabricated using the electro-spray process. Electro-spray deposition (ESD) method is one of the steps of preparing particles from the spray gas production path. The ESD method, which produces nanoscale droplets, together with the evaporation of the nanoparticle solvent can produce a nanoparticle whose size is controlled to the size of the nanoscale and create a quantum confinement effect.

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics