How to build and install NEMS and MEMS systems based on nano-microelectronics (Ph.D.)

Author and Researcher: Afshin Rashid

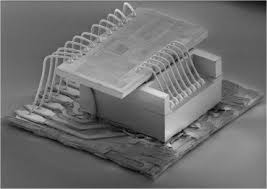

Note: MEMS are integrated into moving micro-structures (with electromechanical components), sensors, actuators, radiation and microelectronic devices. These MEMSs can be manufactured for use in various microstructural technologies such as micromachines.

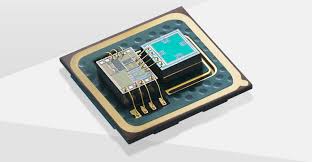

Essential technology in the fabrication of MEMS, CMOS and biCOMS (for manufacturing ICs) and micromachines (for the generation of motion, radiation and energy radiation to micron scale devices and structures ). One of the main goals is to integrate microelectronics with micro electromechanical mechanical devices and structures to produce highly efficient , integrated MEMSs . To ensure high performance, workability, reliability and buildability, CMOS-based bulk manufacturing processes are well developed and must be refined and enhanced.

Micro-machining of Bulk body in MEMS components

Micromachining of the surface and trunk (BULK), in addition to high-aspect ratio (LIGA-like and LIGA) techniques (high-aspect ratio) are the most developed methods of construction. Silicon is the primary layer material used in the microelectronics industry . A number of crystal molds ( 300mm diameter solid and 100mm long solid) are crystallized from very high purity silicon and cut to the desired thickness and then polished by mechanical and chemical polishing technologies . Properties of electromagnetic and mechanical impurities to the crystallization direction and predicted impurities. Depending on the silicon layer, CMOS and biCMOS processes They are used to manufacture ICs, and micromachining of the surface and trunk (BULK), (plus high-aspect ratio (LIGA-like and LIGA) or high-aspect ratio techniques) are the most developed manufacturing methods. Silicon is the primary layer material used in microelectronics. A number of crystal molds ( 300mm diameter solid and 100mm long solid) are crystallized from silicon of very high purity and cut to the desired thickness and then polished by mechanical and chemical polishing technologies. Properties of electromagnetic and mechanical impurities to the crystallization direction and predicted impurities. Depending on the zeros Layer silicon CMOS processes and biCMOS for IC manufacturing processes are used and category listed, such as: Fountains n) well-n, (spring p (well-p (or springs combined (well- twin. (The main steps are: : Diffusion, oxidation , Polysilicon valve arrangement , Optical photolithography, Masking gate formations , Etching, Metal metallization, Wire bonding , (Etc.) We outline the major processes and steps involved in building MEMS.

Processes classified as:

N well-n fountain (well-p) (or well-twin fountain) The main steps are: diffusion, (oxidation)

(oxidation, (polysilicon valve arrangement), (optical engraving photolithographology), gate formations

Masking, etching, metal metallization, wire bonding, etc. We outline the major processes and steps involved in MEMS construction.

Step 1: Crystallize Silicon Dioxide:

( Silicon dioxide is thermally crystallized on a silicon base . For example, crystallization can be performed in a steam-filled space at 1000 ° C for one hour. Silicone surfaces with a layer of diameter 5 / 0 to 1 micron crystal silicon oxide covered (the thickness of the oxide heat thus spreading water vapor in the silicon oxide to a few microns is limited.) silicon dioxide without changing the surface layer deposition, but the process is so slow is a thin membrane pressure is minimized. nitride, silicon may also be deposited and the thickness a Is limited to 4 to 5 micrometers

Helle 2: (Resistance)

(photoresist): A light-resistant material (light-sensitive material) used in silicon dioxide coating. This action can be accomplished by rotating the suspended light resistor in a solvent. The result of rotating and removing the solvent is an optical resistor with a thickness of 0.2 to 2 microns. The optical resistance of the seals to remove the solvents from the inside is completely baking and soft .

Stage 3 (subject to optical engraving and its development : (Photolithography Exposure, and Development)

Optical Resistance Like an optical engraving mask ( optical mask), it is exposed to UV light. This optical mask blocks the path of light and defines a pattern to ensure optimal surface mapping . Optical masks are usually made using melted silica and light transparency that is subject to effective wavelength, width and thermal expansion . On a glass surface or (quartz) a layer of opacity is passed as a sample. ( Usually chrome layer with hundreds of angstroms thick). An optical mask is manufactured based on the shape of the required poly- silicon shell . Pregnancy mapping is determined by mask. The optical resistor is then separated. In a positive light-positive light, Molecular weight reduces optical resistance and eliminates optical resistance by selectively lowering molecular weight materials .

Step 4 (etch ( silicon dioxide): silicon dioxide pen )

Silicone dioxide is pen . Residual light resistance is used as a hard mask that protects the silicon dioxide coating. Light resistance is eliminated by etching wet ( hydrofluoric acid , sulfuric acid and hydrogen peroxide) or etching dry ( by oxygen plasma). The result is a thin film of silicon dioxide on the silicon base .

Step 5 (polysilicon Deposit):

(Screen thin polysilicon, the dioxide silicon deposited there. For example, polysilicon can be in LPCVD at 600 ° C in a confined space silane (SiH4) deposited there. Sedimentation rate in normal conditions 65 to 80 Å Precision (Almin, which minimizes internal pressure and prevents bending and folding . (Thin polysilicon film should be non- pressurized or have a tensile internal pressure). Thin film thickness exceeds (4) ) Is micron.

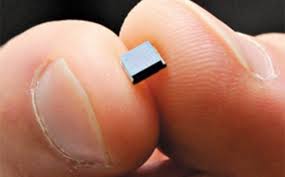

Conclusion on the method of fabrication and reproduction of MEMS system

Thanks to the work done in the field of NEMS, MEMS, today the industry is moving more towards micro and nanoscience. Therefore, research in this field seems to be essential, leading to access to advanced science and technology. Including future work in this area must be made optimum design of MEMS and achieve the kind of reform it is to work in other sciences.