Section "Nanospin Electrons" - Nanoelectronics

Electrostatic Nano Spin Electrons Nano ESD in the structure of nano electrical devices

Researcher and author: Dr. ( Afshin Rashid)

Note: Electrostatic ESD semiconductor nanospin electrons were made using the electrospray process. The electrospray deposition (ESD) method is one of the steps of particle preparation from the gas spraying process. The ESD method, which produces nano-spin-sized droplets of electrons , together with solvent evaporation of the nano-droplets can produce nano-spin electrons whose size is controlled to the nanoscale size and create a quantum confinement effect.

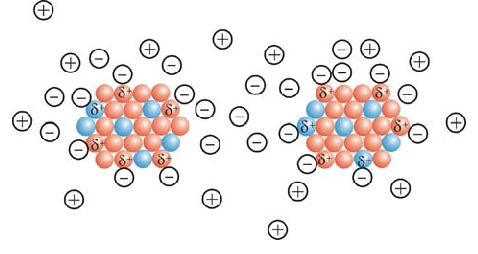

The surface atoms of "nano spin electrons" are not compensated in terms of energy. In general, the results of nanoparticle energy growth can be expressed as the total energy of atoms on the surface of the particle. The freedom of movement of atoms on the surface of nanostructures is limited and only vibrational movements and the movement of electrons are possible. These two electrokinetic reactions are dependent on each other because the displacement of electron clouds of atoms definitely changes the vibrational frequencies of the bonds of atoms of "nano spin electrons" . On the other hand, changing the location of valence electrons in the bonds changes the polarity of the bond and the so-called supermolecular bodies . In this case, electron transfer to a higher energy level becomes possible.

"Nano Spin Electrons" alloys have a high ESD electrostatic property , which makes them suitable for electromagnetic nanomolecules or electromagnetic nanocarriers . In addition to this, the electromagnetic property of the surface of these nanoparticles allows surface active materials to be placed on the surface of their nanoparticles , which can be used to dissolve "nano spin electrons"Surface coating is an inseparable component of electromagnetic nanoparticles so that they can be used. Although "nano-spin electrons" are not attracted to each other due to their super-paramagnetic property, but due to the high energy of the surfaces, electromagnetic nanoparticles tend to accumulate and They are accumulated. The electrostatic stability of nanomolecules is not suitable for nanoparticles; Although the repulsion of charges on the surface of "nano spin electrons" can prevent their accumulation, but in the presence of a catalyst or other electrolytes in the internal environment of ESD electrostatic nanoparticles, these charges are neutralized. Electromagnetic (Active) properties in the coating of nanoparticles, like a barrier, prevent their accumulation, and chemical functionalization creates suitable and efficient properties for nanoparticles . Molecular weight and geometrical orientation exist on the surface of nanoparticles in various forms. Layers that make electromagnetic nanoparticles fully active. It prevents nanoparticles from accumulating.In addition to organic coatings, the core-shell structure is also used for the optimal use of "nano-spin electrons" and electromagnetic nanoparticles

Conclusion:

Electrostatic ESD semiconductor nanospin electrons were fabricated using an electrospray process. The electrospray deposition (ESD) method is one of the steps of particle preparation from the gas spraying process. The ESD method, which produces nano-spin-sized droplets of electrons , together with solvent evaporation of the nano-droplets can produce nano-spin electrons whose size is controlled to the nanoscale size and create a quantum confinement effect.

Researcher and author: Dr. ( Afshin Rashid)

Specialized doctorate in nano-microelectronics