- Nanoelectronics and the effect of quantum confinement

Electronic nanostructures and the effect of quantum confinement

Researcher and Author: Dr. ( Afshin Rashid)

Note: Electronic nanostructures are divided into four categories based on their dimensions, which are in the nanoscale: zero-dimensional, one-dimensional, two-dimensional nanomaterials, and three-dimensional bulk nanostructures , which can be produced by top-down or bottom-up methods. Due to their very small size, nanostructures exhibit special properties, sometimes different from other conventional materials, in electrical conductivity.

In general, nanostructures have three dimensions: length, width, and height. If at least one of these dimensions is on the nanotechnology scale (1-100 nanometers), the material is called a nanostructure. Nanostructures are divided into different categories depending on how many dimensions they have on the nanotechnology scale. One of these categories is based on the number of free dimensions. A free dimension is a dimension that is not on the nanoscale and can have any value. Energy structures (levels or bands) of materials exist along each of the dimensions of length, width, and height. In other words, every three-dimensional object has three separate energy structures along its three dimensions, the result of which expresses the energy structure of the entire material. Dimensions of nanostructures that are on the nanoscale have so-called quantum confinement. For example, thin layers that have discrete energy levels in one dimension.

Quantum confinement means that due to the dimensional constraints at the nanoscale, the energy bands become discrete, and the greater the confinement (smaller the dimensions), the greater the distance between the energy levels. Therefore, one of the main differences between different types of nanostructured materials is the number of continuous energy bands and discrete energy levels in three dimensions, which leads to large variations in their purity.

_env.gif)

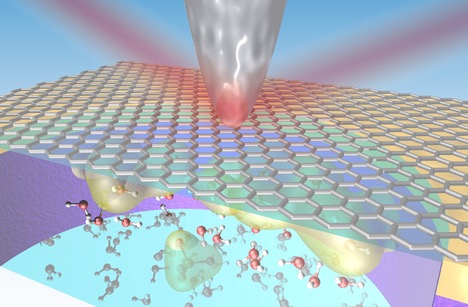

Using nanoparticles under certain conditions, electronic components can be produced. This method is also suitable for producing small-sized memory and circuits. Nanoparticles are the most common elements in nanoscience and technology, and their interesting properties have led to their wide variety of applications in the chemical, medical and pharmaceutical, electronics and agricultural industries. According to their chemical composition, these particles are divided into metallic, ceramic, polymer and semiconductor types. Chemical synthesis and solid-state processes such as grinding and vapor condensation are common methods for manufacturing nanoparticles. Controlling the production process to achieve nanoparticles with appropriate properties is obvious. In this regard, determining the characteristics of nanoparticles with microscopic, structural analysis methods and determining size and surface, etc. Examining molecular connections that are usually formed by molecules adhering to metal electrodes can reduce the dimensions of molecular devices. These connections have great potential to behave and function similar to conventional electronic components. These molecular devices can be suitable alternatives or complements to conventional technologies and create new capabilities in these technologies.

Researcher and Author: Dr. ( Afshin Rashid)

Specialized PhD in Nano-Microelectronics