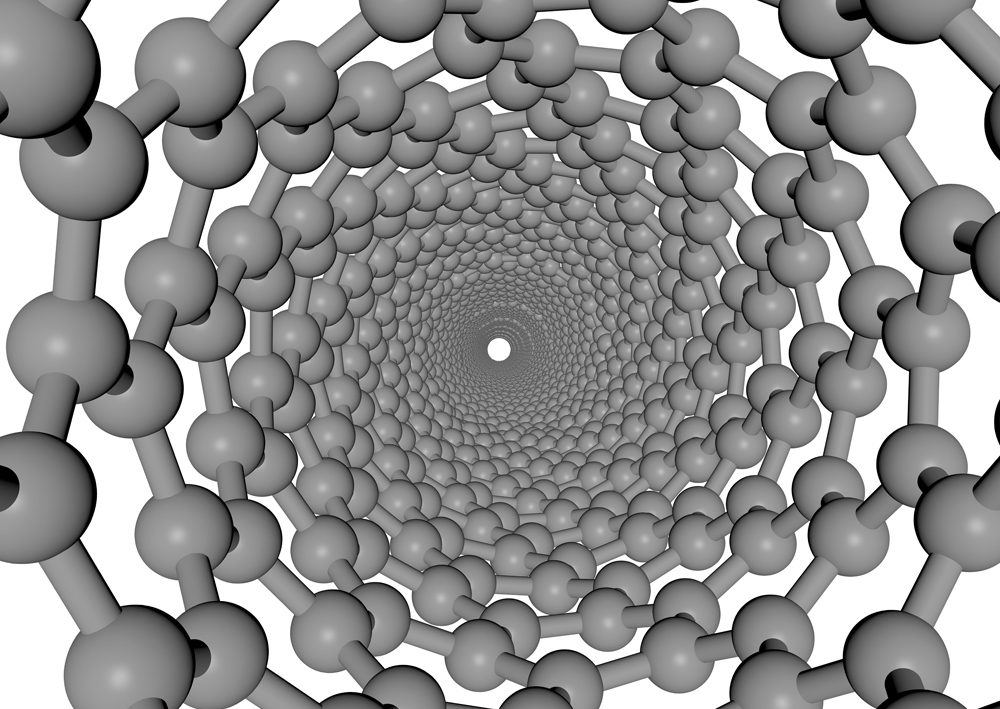

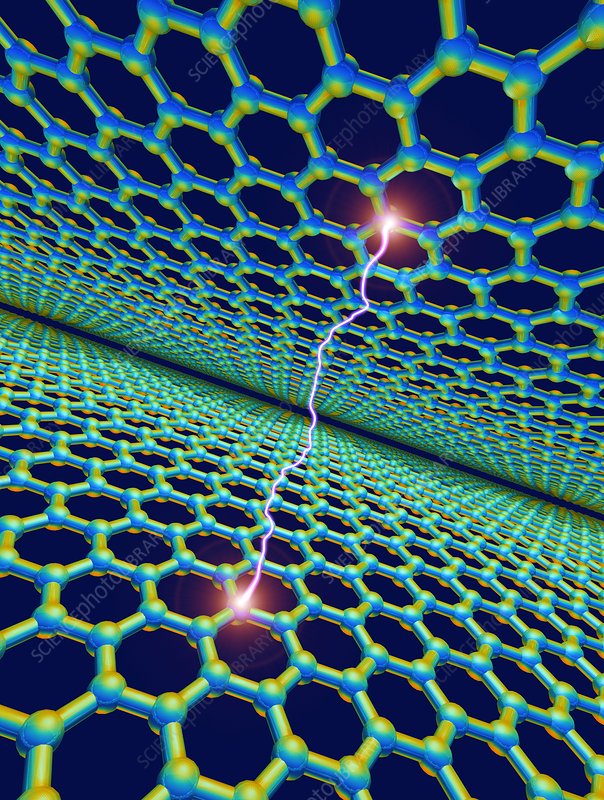

_Part of the process (discharging) for electric nanotubes

Applying pressure on a nanotube can change its (electrical properties) that depending on the type of stretching of a nanotube, its electrical conductivity can be increased or decreased.

Researcher and author: Dr. ( Afshin Rashid)

Note: The smooth wall surface of nanotubes makes the amount of gas passing through them much higher than the normal microporous membranes that are used in gas separation. Therefore, gases such as hydrogen and carbon dioxide can be separated by conduction in nanotubes. Applying pressure on a nanotube can change its electrical characteristics, which can increase or decrease its conductivity depending on the type of stretching of a nanotube.

This is due to the change in the quantum structure of electrons. Therefore, it is possible to make transformers or transmission devices based on nanotubes, which are highly sensitive to the application of very small forces. Also, the ability of nanotubes to sense very small changes in pressure and convert this pressure into an electrical signal can help in making nanotube switches sensitive to very small changes in pressure.

MWNT and SWNT nanotubes at room temperature have the highest electrical mobility coefficient than any other known material. By placing a nanotube under the magnetic layer or by adding electrons or holes to the nanotube, magnetic properties can be created in the nanotube. This property makes it possible to predict the construction of devices in which the magnetic and electrical connections are separated . have became. Magnetic coupling can be used for magnetic polarization of nanotubes - manipulation of spins - and non-magnetic couplings can be used for voltage-current electrodes. Their magnetic power can also be measured . Single-walled carbon nanotubes are composed of only carbon and a simple sheet structure of regular hexagons. Some single walls can be conductive or semi-conductive. This high electrical conductivity depends on the exact geometry of the carbon atoms. Since the beginning of the work on single-walled materials, they have been referred to as a one-dimensional phenomenon. The reason for the interest in these single-walled nanotubes and the effort to replace them in the industry is based on theoretical calculations and laboratory effects on excellent mechanical properties. And their electrical conductivity is like that of metals. The production of single-walled nanotubes has a high cost and it is difficult to produce and stabilize their properties during nanotube processing. Since the use of nanotubes in strengthening polymers improves thermal and electrical properties, the use of multi-walled carbon nanotubes has increased to improve mechanical properties. On the other hand, the existing techniques for the production of single-walled nanotubes are not efficient enough and do not bring the required purity. Purification of these materials is very laborious and may eventually damage the nanotube structure.

Conclusion :

The smooth wall surface of nanotubes makes the amount of gas passing through them much higher than the normal microporous membranes that are used in the separation of gases. Therefore, gases such as hydrogen and carbon dioxide can be separated by conduction in nanotubes. Applying pressure on a nanotube can change its electrical characteristics, which can increase or decrease its conductivity depending on the type of stretching of a nanotube.

Researcher and author: Dr. ( Afshin Rashid)

Specialized doctorate in nano-microelectronics