_ Department of nano laser and electronics

Electronics and industrial nano lasers industrial Nano Laser structure and function

Researcher and author: Dr. ( Afshin Rashid)

Note: One of the broadest fields of nano laser is its presence in the industry. Nano laser has wide applications in the manufacturing and production industry , the reason for using nano laser in the industry is its significant advantages compared to other traditional laser manufacturing and manufacturing methods.

Nano laser cutting is a process in which a piece is cut using a nano laser beam. In this method, small parts can be cut with high precision or parts with large dimensions and thickness. By changing the focus conditions of the nano laser beam, it is easy to cut different materials with the nano laser. Nano laser cutting is a non-contact process, which has many advantages. For example, side effects such as distortion or tearing caused by contact are reduced in the workpiece. In addition, due to the lack of direct contact , nano laser cutting is safer than other laser cutting methods.

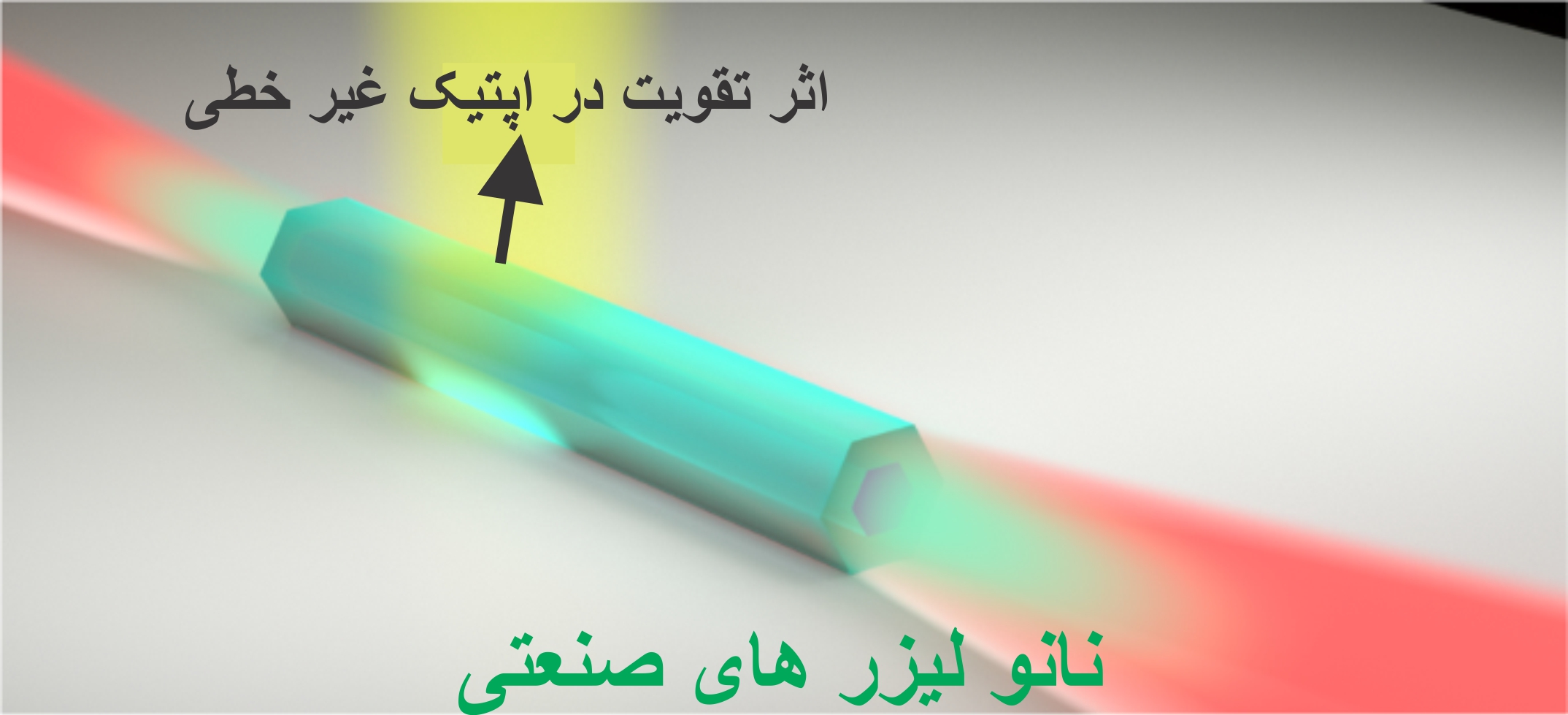

(Industrial Nanolaser) is a laser that on the nano scale , these tiny lasers can be adjusted quickly and together with the small footprint, make them ideal candidates for optical computing on a chip . The intense optical fields of such lasers also enable the amplification effect in nonlinear optics or surface-enhanced scattering (Raman Raman) , thus paving the way for integrated nanophotonic circuits , generally nanolaser enhancement or amplification . It is a process in which the environment transfers part of its energy to the emitted electromagnetic radiation , and as a result, the optical power increases. This is the basic principle of all lasers. Quantitatively, gain is a measure of the ability of a laser medium to increase optical power.

Researcher and author: Dr. ( Afshin Rashid)

Specialized doctorate in nano-microelectronics