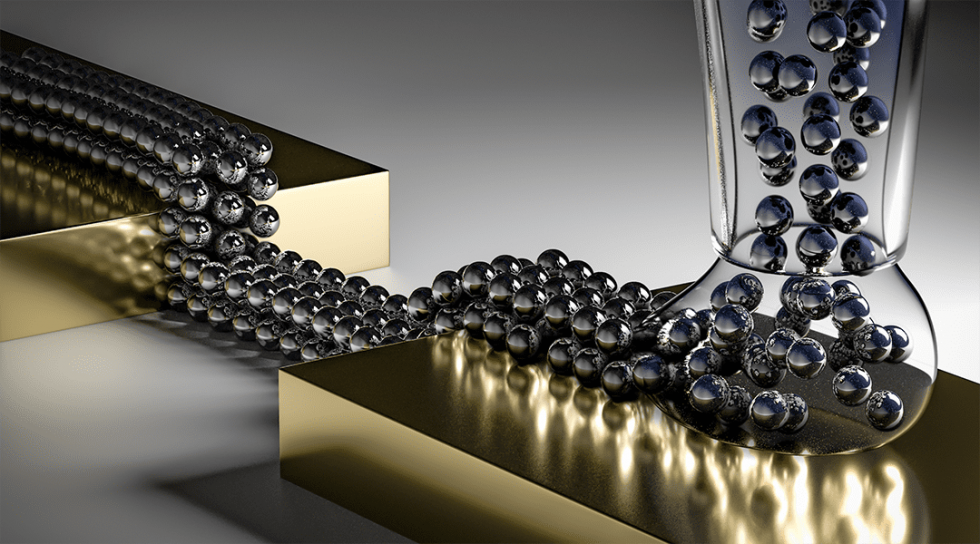

The construction of integrated circuits is a model for the need for lithographic techniques in modern technology (between 10 and 20 nanometers) PhD in nano-microelectronics

Researcher and author: Dr. ( Afshin Rashid)

Note: Since the idea of integrated nanoelectronics is designed and developed by integrating all the circuit elements required for an electronic device by integrating it into a semiconductor block , the development of appropriate manufacturing techniques. Due to its high power, optical lithography is a suitable method for this construction.

In addition, nanoelectronics and nano-lithography can cope with the increasing demand for resolution in each new generation of electronic devices. In the optical lithography is considered to be one of the main pillars electronics. Modern electronics would not be possible without the extraordinary properties of semiconductor materials and powerful technology such as optical lithography. Thanks to optical nan lithography, with each new generation of integrated circuits, doubling the number of transistors was simply not possible, given that the total footprint of a modern transistor is about 100 nanometers × 100 nanometers, or the equivalent of 10 10 transistors. At 2 cm , it is difficult to imagine that the next significant steps will be taken to reduce the size.

Nevertheless, nanoelectronics approaches are being scrutinized as a possible alternative to existing patterns, and nano-lithography techniques remain the cornerstone of all new technologies. On the other hand, nanolithography is important not only in the fabrication of microelectronic components themselves, but also in other related processes. It should not be forgotten, for example, to edit the citation circuit and mask the repair processes, in which the ion beam is concentrated, the ion beam is concentrated by the precipitated beam, the electron beam is concentrated by the nano-lithography, and the concentrated electron beam is deposited by the deposited electron beam . Nano-lithography is commonly used in laboratory research to model materials and fabricate proof devices. Although much of the research does not ultimately lead to a commercial application, it's a wealth of nanolithographic resources and equipment. In fact, it is well known that the properties of materials change with the size of their dimensions with the corresponding physical lengths such as the average free path of electrons, magnetic interactions, the cohesion length of superconductors, and so on. As a result, research activities including the study of changes in physical properties and the discovery of new phenomena at the nanoscale are ubiquitous and require the modeling of materials of interest. Also, the discovery of new devices with commercialization capability is needed as the first step to building a small batch of them. Such prototyping or proof-of-concept construction requires a lithographic infrastructure. For a small number of units in the prototyping stage, fabrication cost is generally not a major issue and various nano-lithography techniques can generally be used.

Conclusion :

In addition, nanoelectronics and nano-lithography can cope with the increasing demand for resolution in each new generation of electronic devices. In the optical lithography is considered to be one of the main pillars electronics. Modern electronics would not be possible without the extraordinary properties of semiconductor materials and powerful technology such as optical lithography.