Composite nano-lithography and manufacturing of nanoelectronic devices and tools (PhD in nano-microelectronics)

Researcher and author: Dr. ( Afshin Rashid)

Tip: We apply a set of techniques using a nanoparticle solution, which creates a very thin layer on the substrate, and is used as a sacrificial layer during the nanoparticle process.

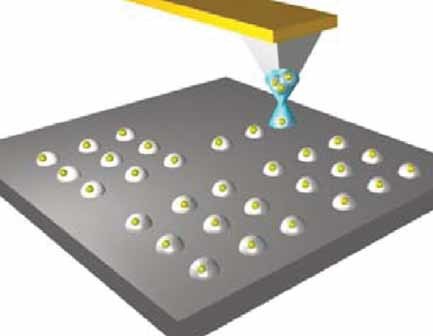

Due to the interaction between the nanoparticles, they can organize themselves and create a thin layer that creates holes between them, a technique originally called natural lithography . Due to the integration nature of colloidal particles and their hydrophilic properties, they form a colloidal crystal with arranged holes through which the material of interest penetrates and settles on the substrate. For example, polystyrene latex nanospheres can be used. The precipitated material on the nanoparticles disappears after the sample is immersed in a suitable solvent and sonicated. This process is similar to a removal process . The advantages of this technique include wide patterns, simplicity, good resolution and the ability to combine with other lithographic techniques. On the other hand, this technique creates problems due to the limited forms available for patterned applications, the arrangement of nanoparticles and the existence of point defects.

In general, if two lithographic techniques complement each other in terms of resolution or pattern area, it makes sense to combine them into a single instrument. This approach has been used to build single-electron transistors , combining direct laser writing for large areas of exposure and combining thermal probe lithography for high-resolution patterns , combining electron beam lithography and scanning probe lithography using a durable layer. It is a combination of nano-lithography, in the process of mixing and matching. In this sense, it typically requires the continuous use of a large area lithography technique for non-critical dimensional patterning and a high-resolution lithography technique for modeling the smallest dimensions, with appropriate protocols for aligning both lithographic stages. Combined nano-lithography has also been used to perform sequential exposure to chemical resistances enhanced by optical lithography and electron beam lithography. Oriented copolymer block nano-lithography is a combination of top-down lithography and self-organizing two polymers from the bottom. Up to produce high-resolution nano-pattern in large areas . Typically, self-organizing copolymer blocks are randomly oriented and lack long-term order , but the previous top-down pattern provides the basis for directional copolymer block lithography. , Combined nanostratigraphic irradiation of a substrate causes preferential growth of semiconductor materials in irradiated areas, which can be used to construct regular arrays of semiconductor points.

Conclusion :

We apply a set of techniques using a nanoparticle solution, which creates a very thin layer on the desired substrate, and is used as a sacrificial layer during the nanoparticle process.