Ionization potential in the structure of micro-nanoparticles and resistance barrier PhD nano-microelectronics

Researcher and author: Dr. ( Afshin Rashid)

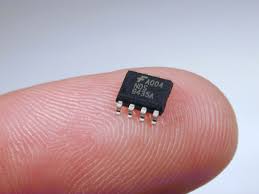

Note: In the amplification of nanotransistors and nanochips, the extraordinary nanoelectronic properties of each grain are also used effectively, while in the amplified components it also increases dramatically, because each of its tiny nano-electron components ranges from hundreds to Thousands of layers are formed.

In the amplification of nanotransistors and nanopips, the properties of nanoelectronics are significantly improved , such as: increase in Yang coefficient, tensile strength, resistance to deformation due to heat, fire resistance, barrier resistance (ionic conductivity) Another advantage is that they do not have a significant effect on the optical properties of the polymer, the optical thickness of a single nano-electron layer is much less than the wavelength of visible light, and they are optically transparent and almost colorless.

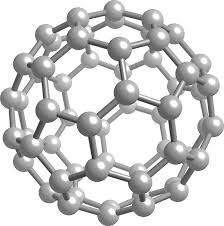

In the amplification of nanotransistors and nanopips based on electronic nanotechnology, the change in the distance between the atoms of the particles and the geometry of the particles also affect the electronic properties of the material. As the particle size decreases, the electrical bonds in metals become finer. In the structure of nanoparticles and resistance barrier, the electronic quantity that is more easily available is the ionization potential and in the ionization potential in the size of small nanoparticles (finer particles) is more, ie with increasing particle size, their ionization potential decreases. Increasing the surface-to- volume ratio and changes in electronic geometry and structure have a strong effect on the chemical interactions of matter, and for example the activity of small particles changes with the number of atoms (and therefore the particle size).

In the amplification of nanotransistors and nanochips, two methods are considered for manufacturing: bottom-up manufacturing method and top-down manufacturing method. In the bottom-up construction method, materials and materials are made from the molecular surface based on the principles of molecular chemistry, just like a wall made by stacking brick by brick. In the top-down manufacturing method, nano-objects are made in larger quantities without atomic control.

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics