Nano-lithography, E-Beam (nano-electronics _Nvry) focused beam of electrons (Doctor of nano-micro-electronics)

Researcher and author: Dr. ( Afshin Rashid)

Note: Writes arbitrary and complex patterns using the focused beam of electrons. The advantage is that almost any pattern can be created. The disadvantage of commercial production is that the processing time of individual wafers can be relatively long (tens to thousands of hours).

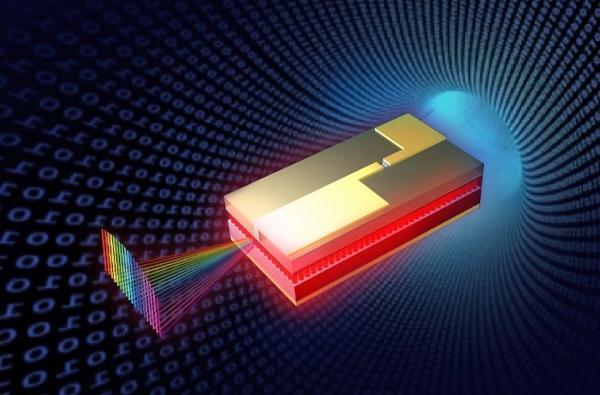

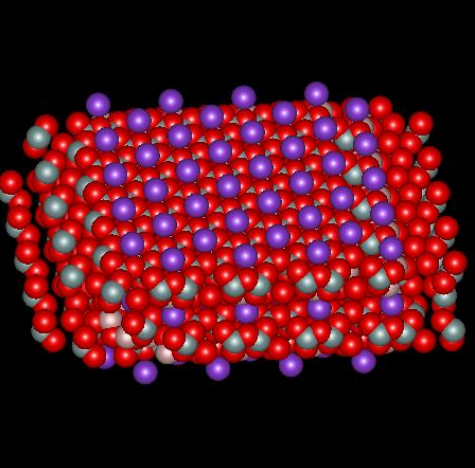

Nano-lithography, which is similar to the production of standard semiconductors, generally uses methods to create an image in the polymer resist layer. This image is then used as an etch mask to transfer the nanoscale pattern to the target material. Nano-lithography methods include interference lithography, electron beam lithography (electron beam) and nano pattern repetition (for sidebar definitions). In general, each of these methods is optimal for some nanostructure patterns, materials, and volumes required. As a production method, nano-lithography supports a wide range of integration modes for optical circuits.

Nano-lithography is the art of creating structures at the nanometer scale. It may be used to create integrated circuits and components for semiconductor technology, where the ability to produce the smallest transistors and circuits may not only make it possible to create smaller devices, but can also help increase the efficiency and performance of components. Advances in lithographic methods have also made it possible to construct complex structures that can be used for microelectromechanical or nanoelectromechanical devices (MEMS or NEMS). Such miniature machines have previously been used as pH sensors and transistors, but there are many future advances in such technologies as the use of devices for drug delivery.Nanolithography is a branch of nanotechnology and is the name given to the process of printing, writing, or engraving patterns on a microscopic surface to create ultra-small structures. This process is commonly used to create smaller and faster electronic devices such as micro / nanochips and processors. Nano-lithography is mainly used in various fields of technology from electronics to biomedicine.

Conclusion :

Writes arbitrary and complex patterns using the focused beam of electrons. The advantage is that almost any pattern can be created. The disadvantage of commercial production is that the processing time of individual wafers can be relatively long (tens to thousands of hours).

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics