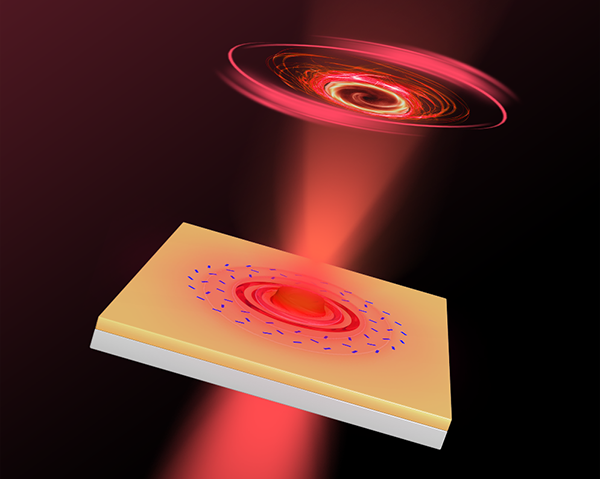

Note: The ability of accelerated ions to scatter atoms on the surface of materials is very suitable for recreational lithography. Thanks to the development of ion beam focusing technology in ion microscopes, this method has become a nanoscale technique with very high lateral resolution in the range of less than 10 nanometers.

Sources nano-lithography and focused ion beam with respect to stability and ease of use are mainly based on nano-technology was , scanning focused ion beam on the surface of a material eliminates material with the desired pattern and precision nano-scale, and to Conceptual design uses focused ion beam nano-lithography and integrates similar components: sources, extraction and acceleration, optics, scan windings, sample stage, electron detectors and more. Interestingly, ionized beam nano-lithography equipment provides the user with all the capabilities of imaging, nanostructuring and analysis of both technologies in a single platform. For this reason, centralized ion beam technology has become very popular for special tasks such as cross-sectional imaging, preparation of nanomaterials, nanomaterials, and circuit editing.

Concentrated ion beam nano-lithography is able to directly remove materials without excessive use of resistorsa direct nanolithographic method, the number of processing steps is minimized compared to other methods. Nano-lithography and focused ion beam as a technique of sequential nanolithography, inherently slow and throughput is much less than the different techniques and the source of metal ion based liquid Ga + the most widespread source for nano-lithography and focused ion beam conversion Has been. In recent years, however, new developments in sources such as gas ion ion sources, plasma sources, and metal alloy sources are the next step in terms of clarity or power.Because the ion-matter interaction is stronger than the electron-matter, it can have detrimental effects on the residual material and alter its physical and chemical properties. Important but key applications for ion beam nanotechnology are concentrated in the semiconductor industry, nanotechnology, and materials science. And sediment from nion lithography's concentrated ion beam requires a gas injection system to produce a local precipitate from a precursor delivered in the form of gas, with the separation of the precursor created by appropriate radiation in the nanoelectric devices . The main advantage of this technique is the selective growth of a substance in the area of interest in one step. Due to the high resolution of ion beam nano-lithography technique , sediments can be grown with high lateral resolution. , But due to much less damage caused in the substrate due to the low linear motion of electrons compared to ions. In contrast, the growth rate and metal content in sediments generally accounted for ionized beam nanolithography.

Conclusion :

The ability of accelerated ions to scatter atoms on the surface of materials is very suitable for recreational lithography. Thanks to the development of ion beam-focused technology in ion microscopes, this method has become a very high-resolution lateral nanoscale technique in the range of less than 10 nanometers.

-

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics

-