_ Department of Integrated Circuits (ASIC)

Integrated circuits (ASIC) _ (high speed and high consumption in terms of electric current)

Researcher and author: Dr. ( Afshin Rashid)

Note: The beginning of ASIC can be traced back to the early 1980s. Around this time, ICs began to make a major impact on the electronics industry. Given the advantages that ICs offered, and the limited number available, efforts were made to create a logic chip that could easily be focused on a specific application. One early initiative by Ferranti, a UK-based company, used what was called an uncommitted logic array (ULA). This design provided customization by changing the metal junction mask.

The first ones ( uncommitted logic arrays or ULAs) contained only a few thousand gates, but later versions had greater levels of flexibility and used different base molds customized by metal and polysilicon layers. In some cases RAM elements were included in the base ULA. From these early developments, a number of different types of ASICs have been developed. Many ASICs are now very complex, and some are mixed-signal ASICs that incorporate both analog and digital circuitry.

Developing and manufacturing an ASIC design including the ASIC design is a very expensive process. In order to reduce costs, there are different levels of customization that can be used. These can reduce costs for designs where large levels of ASIC customization are not required.

There are basically three levels of ASIC that can be used:

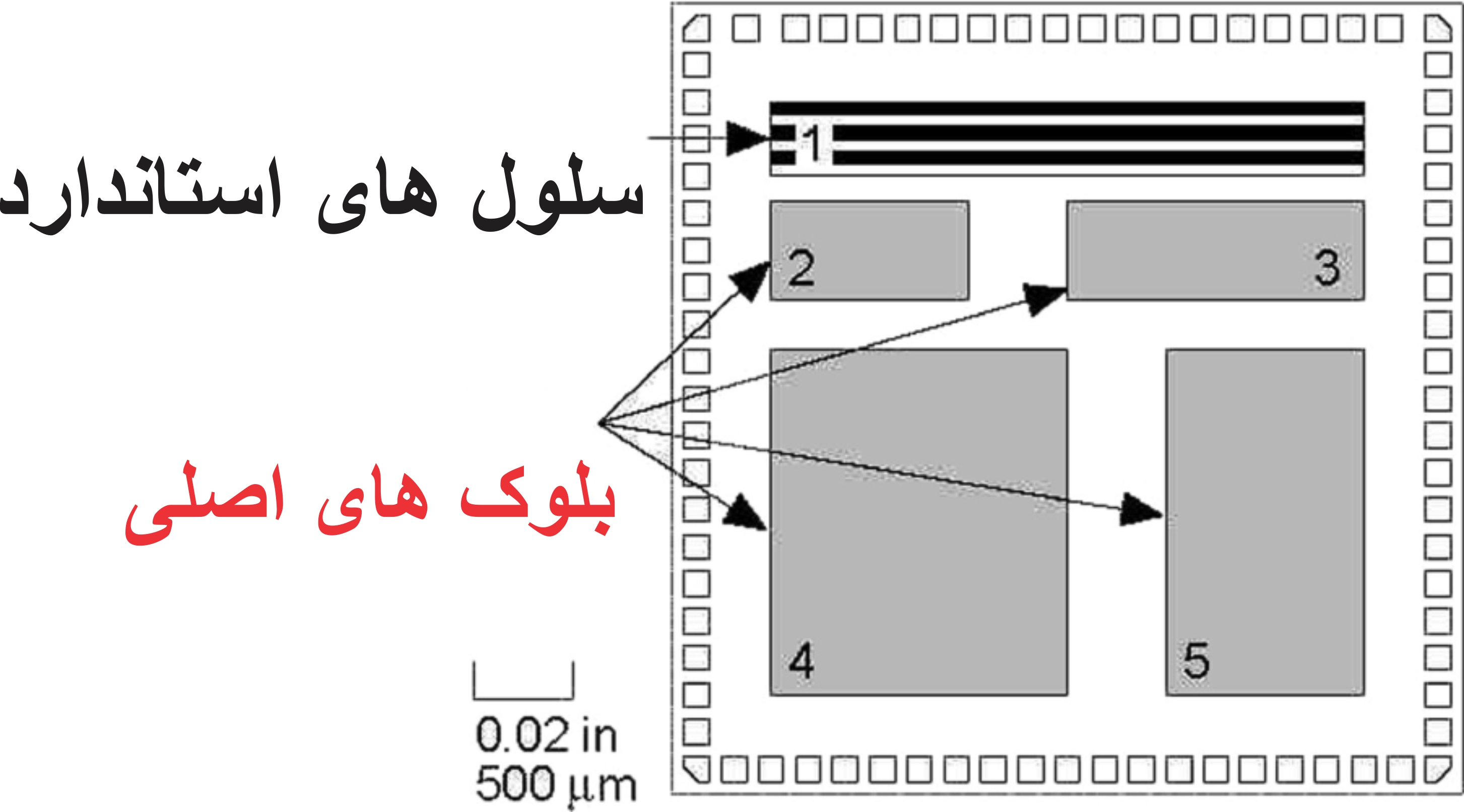

1_ Gate array: This type of ASIC has the least customization capability. Here, the silicon layers are standard, but the metallization layers that allow the connection between different areas on the chip are customizable. This type of ASIC is ideal where a large number of standard functions are required that can be connected in a specific way to meet a given requirement.

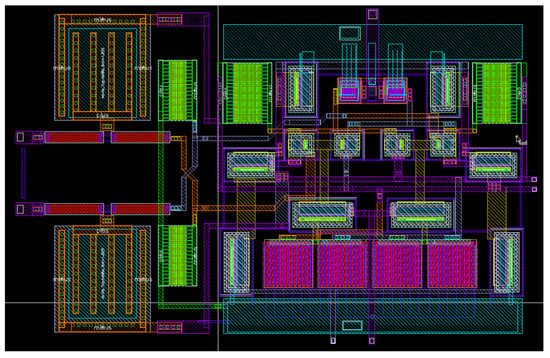

2_ Standard cell: For this type of ASIC, the mask is a custom design, but the silicon is made from library components. This gives a high degree of flexibility, provided that the standard functions are able to meet the requirements.

3_ Full custom design: This type of ASIC is the most flexible because it includes ASIC design down to the transistor level. The ASIC design can be adjusted to the exact requirements of the circuit. While it offers the highest degree of flexibility, the costs are much higher and it takes more time to develop. The risks are also higher because the whole design is untested and not built from already used library elements.

ASIC designs offer a very attractive solution for many high-volume applications. They allow significant amounts of circuitry to fit on a single chip. If the circuits were assembled using dedicated chips, additional components and thus board area would be required. Construction costs will be higher. With sufficient volume, custom chips in ASIC form offer a very attractive proposition. In addition to the cost aspects, ASICs may also sometimes be used because they enable circuits that are not technically viable using other technologies. They may provide speed, and performance not possible when using discrete components.

Researcher and author: Dr. ( Afshin Rashid)

Specialized doctorate in nano-microelectronics