Nanostructure of multilayered Aspatrnyg Espatterning ( Doctor of nano-micro-electronics)

Researcher and author: Dr. ( Afshin Rashid)

Note: In nanoelectronics technology, special parameters and systems must be used to perform such processes. For example, in the metalworking process, the use of copper metal instead of conventional aluminum metal for internal connections between different parts is practically inevitable. However, the rapid penetration of Cu atoms under Si in heat treatment leads to the formation of a copper silica layer and ultimately to the destruction of the electronic component.

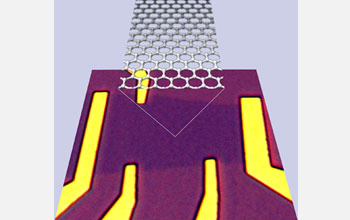

To solve this problem, a middle layer of retardant materials such as Ta, w or Mo is usually used as an penetration barrier to improve the thermal stability of the Si / Cu layer . In the characterization of nanoparticles and Si / Ta / Cu multilayer systems, there is the effect of negative bias voltage on improving the electrical and structural properties of the Ta Sputtering Ta penetration barrier in the Si / Ta system. Surface processes of the Si layer, including combustion, are performed by plasma and ion beam technology. These types of integrated circuits with their unique properties at the nanometer scale have a variety of applications of mesoscopic systems.

Modeling of Si / Cu Nanoparticles Based on a Relationship Between Molecular Mechanics and Solid Mechanics, an energy-equivalent model is used for the mechanical properties and nanomolecular structure of Spaternig layer of materials. Macroscopic properties of nanoparticles such as melting point, boiling point and electrical conductivity. It is done through a sample that is large enough to measure under normal laboratory conditions. When the melting point of a nanomolecule is measured, the behavior of a large number of nanoparticle molecules is actually examined, and this is not true for all materials; When the size of the material is reduced to nanometer dimensions, completely different behaviors and properties may be observed from the same material in large dimensions.The properties of nanomaterials and nanoparticles can depend on its size. This fact may be contradicted by the fact that the properties of materials (solids, liquids and gases) are related only to the atoms and molecules that make up the substance and the type of bond they have, or to the arrangement of the atoms. But everything has changed at the nanoscale, as a result of which the properties of the material may undergo fundamental changes.

Conclusion:

In nanoelectronics technology, special parameters and systems must be used to perform such processes. For example, in the metalworking process, the use of copper metal instead of conventional aluminum metal for internal connections between different parts is practically inevitable. However, the rapid penetration of Cu atoms under Si in heat treatment leads to the formation of a copper silica layer and ultimately to the destruction of the electronic component.

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics