Production methods of nano-transistors with (laser wear) PhD in nano-microelectronics

Researcher and author: Dr. ( Afshin Rashid)

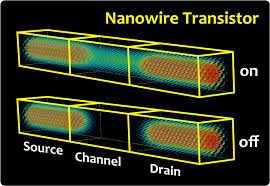

Note: In nanoscience, especially (nanoelectronics) for the production of nano-transistors and nano-chips from carbon nano tubes due to unique properties such as elasticity, conductivity, high strength is receiving much attention. Production methods of these nanostructures are divided into two general categories of methods based on solid carbon and gaseous carbon.

Two common points in nanotube production methods based on solid carbon source such as laser abrasion, arc discharge and use of high temperature environment (between 0111 to 0111 Kelvin) and erosion of solid graphite as carbon source. Despite these commonalities, the morphology, morphology, carbon nanostructure, and production efficiency of carbon nanotubes vary considerably according to the experimental conditions. Before the advent of carbon nanotubes, fullerene was produced using these methods. The production of carbon nanotubes, in addition to the necessary conditions for the production of high temperature fullerene and the absence of oxygen, also requires the presence of a catalyst.

Various mechanisms such as the process of separation of carbon molecules and recombination of atoms, etc. are involved in these high-temperature methods. The main mechanism of these methods is the transfer of energy from the external radiation source of a laser beam or solar radiation to the target material. This leads to erosion of the target material and subsequent formation of plasma. The degree of plasma ionization highlights the importance of energy transfer between the plasma and the target material. The characteristic of plasma and especially the temperature range and concentration of different species in plasma depends not only on the nature and composition of the target material but also on the amount of energy transferred. For the production of nano-transistors and nano-chips, one of the advantages of these methods is the ease of changing process parameters and achieving optimal conditions for the production of carbon nanotubes. A major challenge These methods are impurities in the products. Carbon nanotubes are produced together with other carbon phases and catalyst residues. Most existing oxidation-based purification methods are similar to acid-based methods that will affect the structure of single-walled nanotubes. A favorable approach for purification is thermal materials at 0011 ° C under neutral atmosphere. A graphite plate containing a catalyst is placed in the middle of a quartz tube containing a neutral gas (such as helium and argon). The system is then placed in an oven at 0011 ° C. The laser beam is focused on the graphite plate, resulting in uniform surface evaporation. The carbon vapor is swept by a stream of neutral gas and soaked like soot on various surfaces including a water-cooled copper collector, a quartz tube wall, and the bottom of the plate. Graffiti precipitates. This process depends on many parameters such as the laser beam characteristic, the applied power density, the nature of the target and the environment . For example, a solid target can be simply heated, melted, or evaporated, depending on its power. So far, several approaches have been taken to improve the production efficiency of carbon nanotubes and nanotransistors by laser wear.

Conclusion :

In nanoscience, especially (nanoelectronics) for the production of nano-transistors and nano-chips from carbon nano tubes due to unique properties such as elasticity, conductivity, high strength is much attention. Production methods of these nanostructures are divided into two general categories of methods based on solid carbon and gaseous carbon.

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics