🔬 آز مدارهای اِلکترونیکی

آزمایش (آیسی 741 op-amp) و تقویت سیگنالهای AC & DC در مدارات اِلکترونیکی

پژوهشگر و نویسنده: دکتر ( افشین رشید)

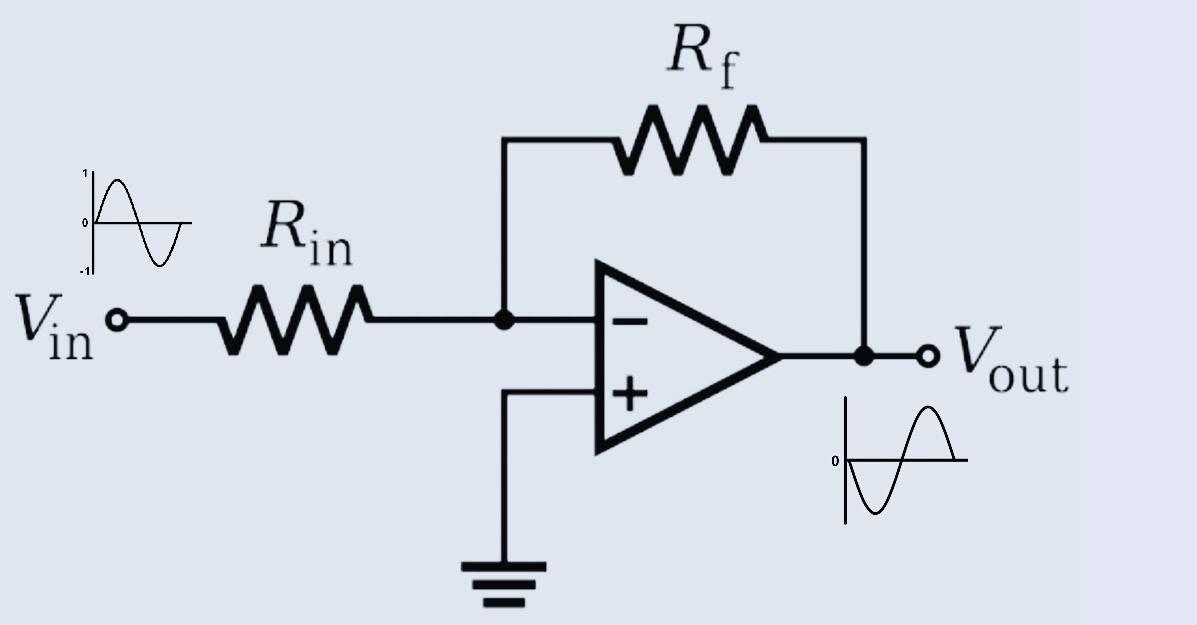

نکته : مدار مقایسه کننده همانطور که در نام دو تکه op_ amp وجود دارد ، دو چیز را مقایسه می کند. در این حالت ، دو سیگنال آنالوگ را مقایسه می کند. یک سیگنال ولتاژ (جریان) وجود خواهد داشت که به عنوان مرجع مورد استفاده قرار می گیرد و سیگنال دیگری نیز که قابل مقایسه است. سپس آمپر مشخص خواهد کرد که کدام یک از دو سیگنال از قدر بیشتری برخوردار است.

_isoi.gif)

مدار معادل یک آمپر op ، مدار است که پارامترهای op amp از نظر اجزای فیزیکی نمایش داده می شوند. یک آی سی opamp آپ امپ از تعداد زیادی ترانزیستور و مقاومت تشکیل از نظر مدار داخلی ، طبقه اول تقویت کننده های عملیاتی شامل زوج دیفرانسیل، طبقات میانی امیتر مشترک وزوج دیفرانسیل وآخر آن کلکتور مشترک(امیتر فالور)میباشد.

این آی سی ها یکی از پر کاربردترین آی سی ها در الکترونیک میباشد که کاربرد زیادی در اعمال جبری دارد. این آی سی ها از پرکاربردترین قطعات الکترونیک می باشند و با اضافه نمودن قطعاتی در ورودی و خروجی آنها می توان مدارها با کاربردهای متنوع طراحی کرد.

از جمله مدارهائی که می توان با آپ امپ طراحی کرد به موارد زیر می توان اشاره نمود:

تقویت کننده با گین مثبت و منفی ، تقویت کننده تفاضلی ، جمع کننده سیگنال ، مدار انتگرال و مشتق گیر ، تبدیل کننده جریان به ولتاژ ، مقایسه کننده ولتاژ و سیگنال ژنراتور ، منبع جریان دقیق ، رگولاتور ولتاژ ، مبدل ولتاژ متناوب به مستقیم و مدار های متنوع دیگر مورد استفاده قرار میگیرد.

فرم کوتاه تقویت کننده عملیاتی op-amp است که نوعی IC کاملا ترکیبی دو حالته است. این ساختمان اصلی مدار های الکترونیکی آنالوگ است که انواع مختلفی از کارهای پردازش سیگنال آنالوگ را انجام می دهد. این آی سی ها برای تنظیم عملکردهای خود از بازخورد خارجی استفاده می کنند و از این اجزا به عنوان دستگاهی چند منظوره در ابزارهای الکترونیکی مختلف استفاده می شود. از دو ورودی و دو خروجی تشکیل شده است ، یعنی ترمینال های معکوس و غیر معکوس. این آمپر IC 741 بیشتر در مدارهای الکتریکی و الکترونیکی مختلف مورد استفاده قرار می گیرد. هدف اصلی این 741 op-amp تقویت سیگنالهای AC & DC و عملیات ریاضی است.

پژوهشگر و نویسنده: دکتر ( افشین رشید)

دکترایِ تخصصی نانو _ میکرو الکترونیک