Technology of making nano-supercapacitors

Note: One of the technologies that has grown significantly in recent years and can be the source of change in various industries, including nanoelectronics in the near future, is the technology of making supercapacitors. It can be said that supercapacitor is a kind of interface between electrolyte capacitors and rechargeable batteries.

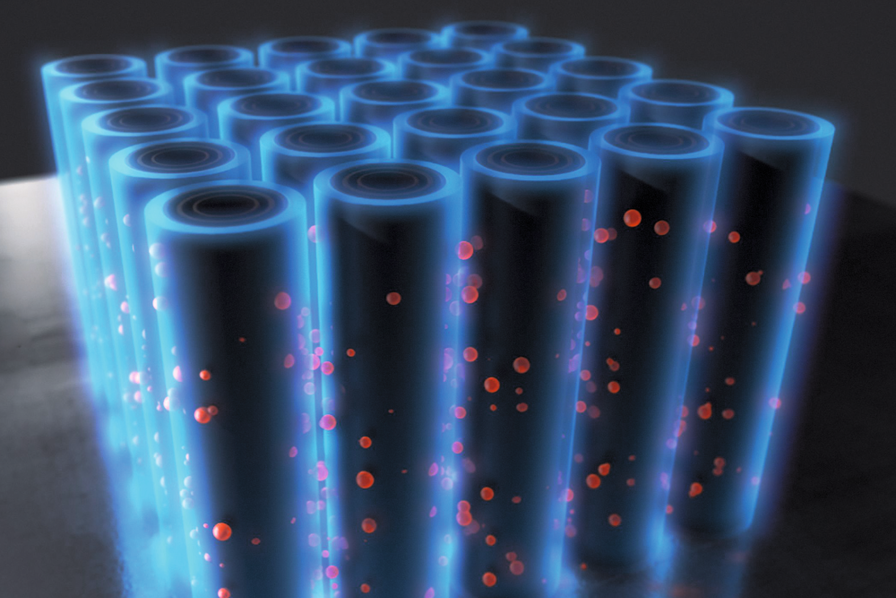

Structure and structure of nano-supercapacitors based on nanoelectronics to store 100 times more load in equal volumes than other types of electrolytes and to charge and discharge much faster than batteries. Of course, these capacitors still store up to 10 times less load in equal volumes than some types of batteries. (Until now, their major use in the electronics industry has been as a backup for SRAMs.) Nanoelectronics A diagram of a capacitor supercharger is shown. The main idea to achieve high capacitance is to reduce the distance between positive and negative charges in the capacitor. The design of these capacitors is such that the thickness of the dielectric layer in them does not exceed one or more molecules. The dielectric nanoplayer is a barrier between positive and negative charges that has a very small thickness. And nanomaterials are electrolytes that contain both positive and negative ions. By placing the potential between the capacitor electrodes, the negative ions move towards the positive electrode and the positive ions move towards the negative electrode. Finally, two capacitors are obtained, which are connected in series

Supporting nanostructures (SRAMs) are memory chips made of carbon nanotubes, although the discovery of small but very strong, flexible, and conductive carbon nanotubes with dimensions the size of DNA strands and the use of Absorb chlorophyll-like microorganisms instead of charge storage capacitors in DRAM and SRAM memory chips. Nanocrystals, the use of which will increase the lifespan of flash memory. And the development of a magnetic material based on the protein ferritin, which will be used to make disk drives and memory chips.

The production and manufacture of memory is one of the largest industrial sectors, but it also faces several technical problems; Problems such as capacitor leakage, structures with increasing complexity, and sensitivity to minor errors due to cosmic rays. The existence of such problems makes it impossible for chip makers to reduce their chip dimensions beyond this. Other notable issues in this area include SRAM chips for large memory cells, the difficulty of placing DRAM and flash memory alongside logic chips, and the slow access time of flash memory and its limited stability.

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics