Mechanism of nanotube growth by CVD method or chemical vapor in the production of nano devices (PhD in nano-microelectronics)

Researcher and author: Dr. ( Afshin Rashid)

Temperature is the most important difference between gas and solid source methods. CCVD typically uses low temperatures, and nanotubes grow at temperatures below 0111 degrees. More than one mechanism can be involved in the growth of carbon nanotubes, depending on the type of gaseous precursor, the catalyst used and the operating parameters . The dissolution-diffusion-deposition mechanism is one of the most common, which is more prevalent in low temperature methods. In this mechanism, catalytic nanoparticles of metal alloys or intermediate metals (such as nickel, iron, and cobalt) are considered spherical or floating on the substrate surface . Hydrocarbon vapors (such as CO, CH4, C2H2, C2H4, and C2H6) when Catalyzes contact with hot particles, decomposes into carbon and hydrogen, and carbon penetrates into the substrate metal.

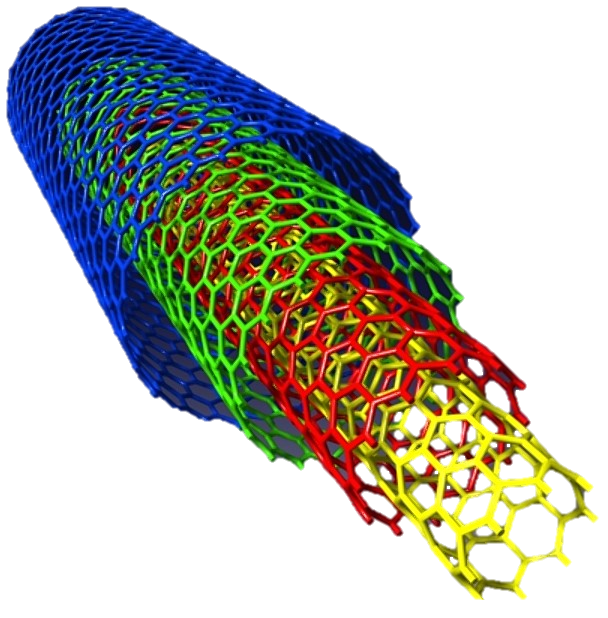

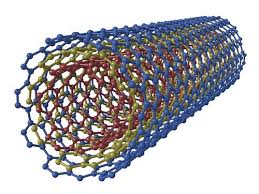

When the carbon atom in the catalyst reaches supersaturation, precipitation and growth of carbon nanotubes begin. If the interaction of the catalyst bed is poor) metal substrate has a contact angle is acute (nanotubes at the bottom of the catalyst (Tipgrowth) and if the interaction of the catalyst bed is strong metal substrate has a contact angle is open. Nanotubes on top of the catalyst to grow the ( growth base) In the first case, it is possible to produce nanotubes with an open head.The physical shape of the deposited carbon The single-walled, multi-walled, amorphous and graphitic carbon nanotubes covering the catalyst nanoparticles depend on many factors such as catalytic particle size and deposition rate. When the deposition rate is equal to or less than the carbon penetration rate, the surrounding graphite layer Catalytic nanoparticles are formed. When the deposition rate is higher than the carbon penetration rate, carbon nanotubes are formed. Catalytic nanoparticle size plays an important role in the growth of nanotubes. Catalytic nanoparticles with a small size (less than 01 nm) are generally active for nucleation and growth of carbon nanotubes.

If the particle size is one nanometer, a single-walled nanotube is formed. Catalytic nanoparticles with a size of 01 to 51 nm lead to the growth of multi-walled nanotubes. Catalytic nanoparticles larger than 51 nm are also coated with amorphous graphite sheets . And the construction of chips and nanotransistors shows the effect of the crystal structure of the catalyst on the shape and structure of carbon nanotubes. Various definitions of changes in the structure of materials for the production of nanoscience electronic chips and elements have been proposed.

Conclusion :

Nanoelectronics is the study of phenomena and manipulation of materials at scales in atomic, molecular and macromolecular dimensions, which leads to a drastic change in the properties of materials (compared to materials in large dimensions).

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics