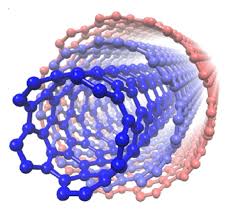

How to control the growth of single-layer and multilayer carbon nanotube molecules (SWCNTs and SWCNTs)

Note: For the controlled fabrication and growth of monolayer and multilayer nanotubes (SWCNTs and SWCNTs), molecular equipment based on SWCNTs is selected in the direction of stenting to obtain nanotubes with similar properties. In the carbon monoxide CVD method, it has been found that the two Co-MCM-41 and Co-MoT catalysts form a narrow distribution system of SWCNTs with (m, n) specific but still produce about 20 types of nanotubes with different (m, n) .

The FeRu bimetallic catalyst in the CVD method with methane produces a narrow distribution of SWCNTs with a diameter of less than (2 to nm.2.1). There are also examples of semiconductor-enriched SWCNT enriched by plasma-intensified chemical vapor deposition (PECVD 23). Semiconductor SWCNTs with 96% purity are obtained using a combination of methods (PECVD) and rapid heating. In this way, enriched samples of metal SWCNTs are grown on pyrolysis of a (monohydroxy homologue) of alcohol as a carbon source on an MgO / Co-Fe catalyst. In this case, the produced SWCNTs contain 65% more purity than metal SWCNTS. The difference is that SWCNTs are produced from atmospheric iron nanocatalysts (helium) or (argon) with different ratios of hydrogen and water at high temperatures, and according to Raman spectroscopy (RAMN) and electrical testing. FET can also achieve 91% efficiency in the production of metal nanotubes

Most synthesis methods have been able to produce one or two major species of SWCNT with a frequency of 20-30% along with many other species with similar diameters. An interesting method for the synthesis of nanotubes with similar chirality is the use of organic synthesis methods. In this way, the shortest armchair nanotubes can be produced with a structure called annular carbon nanotubes by producing SWCNTs molecules. They are produced through cyclic enhancement reactions (Dils-Alder), but none of these industrial methods are truly industrial. If high-purity SWCNTs are used as raw material and as a template for in- center growth , the product quality will be similar to that of the template, and the method will be economically viable, and scaling will be possible.

Conclusion:

These chemical methods are performed after synthesis, separation of SWCNTs based on diameter, metal or semiconductor and optical activity . Regarding chemical methods after synthesis, there are two main strategies: First, using chemicals, selective reactions with certain species of SWCNTs done in plain view and increase its scale. But the purity of the product is not high and the intrinsic properties of SWCNTs change due to chemical reaction. Another strategy is to connect factor groups to specific types of SWCNTs and SWCNTs through covalent interactions . In this way, good returns are obtained for the classification of SWCNTs and there are good recovery methods to obtain the product with good purity. But these methods Can not be easily scaled, because it is difficult to select SWCNTs with (m, n) in large quantities selectively .

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics