Nanoparticles and Bonds in the Manufacture and Duplication of Nanomaterials (Based on Nano-Microelectronics PhD) (Educational-Research Ph.D.)

Nanoparticles or nanoparticles in metal and metal oxide clusters and metal / carbon nanocomposites, in contrast to carbon nanostructures, share in addition to metal and covalent bonds (important in covalent bonds) that self-organize their systems. At the same time, these bonds can increase the electron structure of d metals, thereby increasing the number of individual electrons and the number of magnetic moments of the atom .

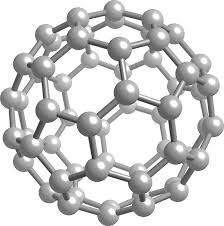

In the manufacture and propagation of nanoparticles, the results of nanoparticle energy growth can be expressed as the total energy of the atoms of the particle surface. Obviously, the freedom of movement of the surface atoms is limited and only vibrational movements and movement of electrons are possible. The two kinetic forms are interdependent because the displacement of the electron clouds of atoms will inevitably alter the vibrational frequencies of the bonds of the atoms. On the other hand, the displacement of the valence electrons in the bonds changes the polarity of the bond and the so-called super-molecule objects , thus allowing the electron to move to a higher energy level. In this respect, metal / carbon nanostructures are the most interesting species studied. In these nanostructures , metal clusters interact with the carbon envelope that protects them from the environment, which is why these nanostructures are called metal / carbon nanocomposites.

Structure of magnetic nano-electrons in bonds

The use of metal / carbon nanoparticles in the form of fine suspensions and sols at specific intermediates for the modification of organic and inorganic polymer materials depends on the electron paramagnetic resonance, which may be associated with the colors, sizes, and properties. Examination of the band gap structure of these devices, in addition to introducing a method for the performance of one-dimensional systems, has enabled the improvement of the nano-microelectric properties of electronic components.

Organic-based devices can be largely mechanically flexible due to the weak intermolecular bonds in their layers. Unlike these organic materials, minerals such as silicon, germanium and gallium arsenide are only used in crystalline states of the electronic device structure, whereby covalent bonds make flexibility impossible.