Amplification of nanotransistors including heterogeneous and homogeneous process (PhD in nano-microelectronics)

Researcher and author: Dr. ( Afshin Rashid)

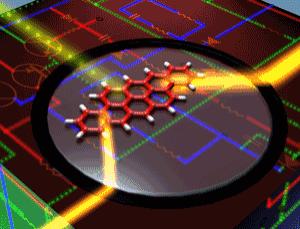

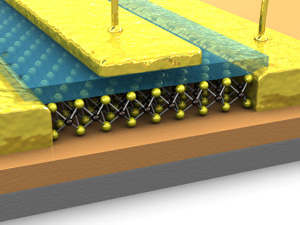

Note: In the method of amplification of nanotransistors and nanotubes with the synthesis of carbon nanotubes based on catalytic chemical vapor deposition (CCVD) involves the decomposition of the carbon source on particles or small metal clusters as a catalyst. This method of amplification of nanotransistors includes The process is heterogeneous and homogeneous. The metals used for these reactions are intermediate metals , such as iron, cobalt, nickel. Compared to arc discharge and laser abrasion, carbon nanotubes generally form at lower temperatures of about 011 to 0111 degrees.

This method is generally more selective for the production of multi-walled carbon nanotubes. Both homogeneous and heterogeneous processes are very sensitive to the nature and structure of the catalyst used in addition to the operating conditions. Carbon nanotubes produced by this method have a longer length (several tens to several hundred micrometers) and defects compared to the arc method. The greater disadvantage of nanotubes is due to the use of lower temperatures compared to the arc method, which does not allow any structural rearrangement.

When the carbon atom in the catalyst reaches supersaturation, precipitation and growth of carbon nanotubes begin. If the interaction of the catalyst bed is poor) metal substrate has a contact angle is acute (nanotubes at the bottom of the catalyst (Tipgrowth) and if the interaction of the catalyst bed is strong metal substrate has a contact angle is open. Nanotubes on top of the catalyst to grow the ( growth base) in the first case possible to produce nanotubes with an open mouth there. the physical form of carbon deposited carbon nanotubes, single-walled, multi-walled, amorphous and all graffiti coating catalyst nanoparticles (elements much like the size of catalyst particles, the deposition rate depends When the deposition rate is equal to or less than the rate of carbon penetration, the surrounding graphite layer Catalytic nanoparticles are formed. When the deposition rate is higher than the carbon penetration rate, carbon nanotubes are formed. The particle size of the catalytic role in the growth of CNTs plays generally catalyst nanoparticles with small size) less than 01 nm (for nucleation and growth of carbon nanotubes are active. If the particle size of one nanometers, nanotubes, single-walled form Catalytic nanoparticles with a size of 01 to 51 nm lead to the growth of multi-walled nanotubes, as well as catalytic nanoparticles larger than 51 nm are covered with amorphous graphite sheets . The effect of the crystal structure of the catalyst on the shape and structure of the carbon nanofiber.

Conclusion :

Amplification methods for nanotransistors and nanotubes by synthesizing carbon nanotubes based on catalytic chemical vapor deposition (CCVD) involve the decomposition of a carbon source on particles or small metal clusters as catalysts. is. The metals used for these reactions are intermediate metals , such as iron, cobalt, nickel. Compared to arc discharge and laser abrasion, carbon nanotubes generally form at lower temperatures of about 011 to 0111 degrees.

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics