Compounds (III-V) The main factor in nano-devices such as nano-emitting light emitting diodes .

Researcher and author: Dr. ( Afshin Rashid)

Note: Optical nano-optical and nanoelectronic devices may make the most of these (III-V) semiconductor compounds. The main reason for the possibility of energy gap engineering in these compounds is unlike silicon.

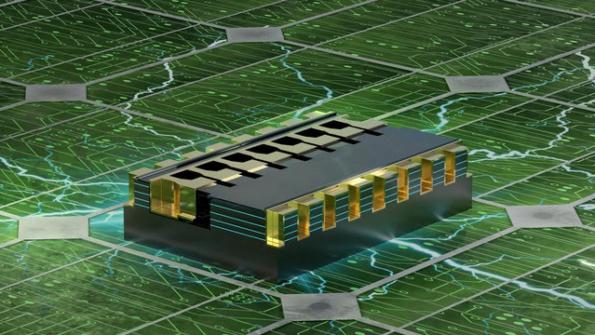

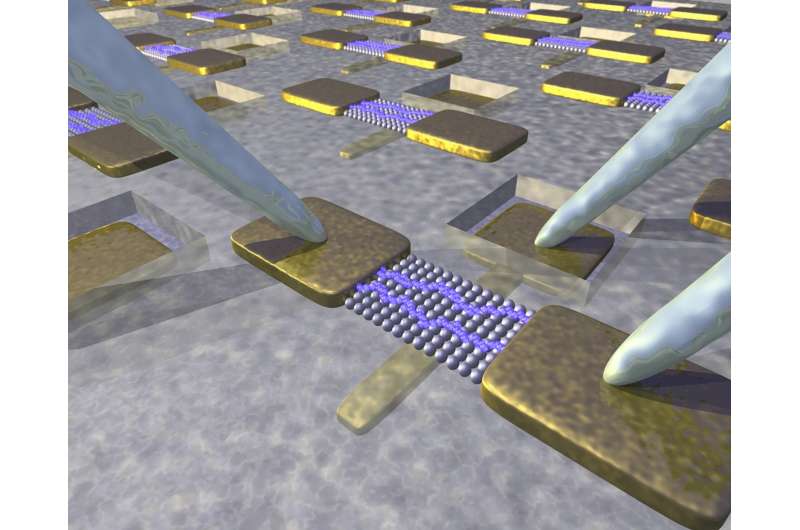

Compounds (III-V) The main factor in nanomaterials such as light emitting diodes is to determine this spectrum, the energy gap in the semiconductor used. To change the energy gap, there is no choice but to use semiconductor compounds instead of semiconductor elements. Decades ago, LEDs were still made with two spectrums of red and green light, but the possibility of making high-brightness blue nano-LEDs remained an unsolved mystery. Production of LEDs with blue light spectrum by GaN It was possible to produce white light with LEDs. Part of the light the most efficient nano LED bulbs are increasingly finding wider application. Optical detectors are key components of these circuits. The main substrate for making these circuits is the photon crystal.Compounds (III-V) of nano-optical and nano-optical devices are among the most common applications of nano-microelectronics. The possibility of connection between the cores of silicon processors and external memory by integrated optical communication channels made of composite semiconductors, with very high data transfer rates in other communication technologies and the connection between processors has attracted to integrated optical nanoelectronics.

Compounds (III-V) of nano-optical devices

III-V Compounds Apart from some elements of group 4 of the periodic table, namely Si and Ge, which are semiconductors, compounds of elements of groups 3 to 5, group 2 to 6, as well as group 4 to 4 alloys also have semiconductor properties. Even some compounds of the three elements of these groups, such as AlGaAs and InGaN, have semiconductor properties . At the beginning of the study of these compounds and research on them, it was thought that they would soon replace silicon, because the possibility of engineering and obtaining some properties, which It did not exist in silicon, it was possible for them. However, due to the lack of suitable insulation for use in transistor gates, as well as the high cost of the elements and the coating process of V-III composite semiconductors, silicon and finally silicon-germanium alloy still remain used as the main semiconductor.It should be noted that silicon oxide, which is easily layered with high purity, is a very good insulator for this purpose. Nowadays, in integrated circuits with a channel length below 50 nm, alternative oxides with higher dielectric coefficients, such as zirconium oxide ZrO2 and hafnium oxide, are obtained. He started. For example, in xAs-AlxGa1 and xN-InxGa1, a change in x leads to a change in the energy gap, and many of the properties of these semiconductor composites lead to the energy of the structural strip. Compounds (III-V) find nano-optical devices (xAs-AlxGa1) in (x <45.0 mode) along with changes in the distance between the edge of the capacity strip and the edge of the conduction strip by changing x in three different directions of wave propagation.

Conclusion :

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics