Amplification of electronic nanoassemblies by interfering nano-lithography (IL) method (PhD in nano-microelectronics)

Researcher and author: Dr. ( Afshin Rashid)

Note: The concept of Nano-assemblies is summarized in all the information and code needed to produce a similar inventory .

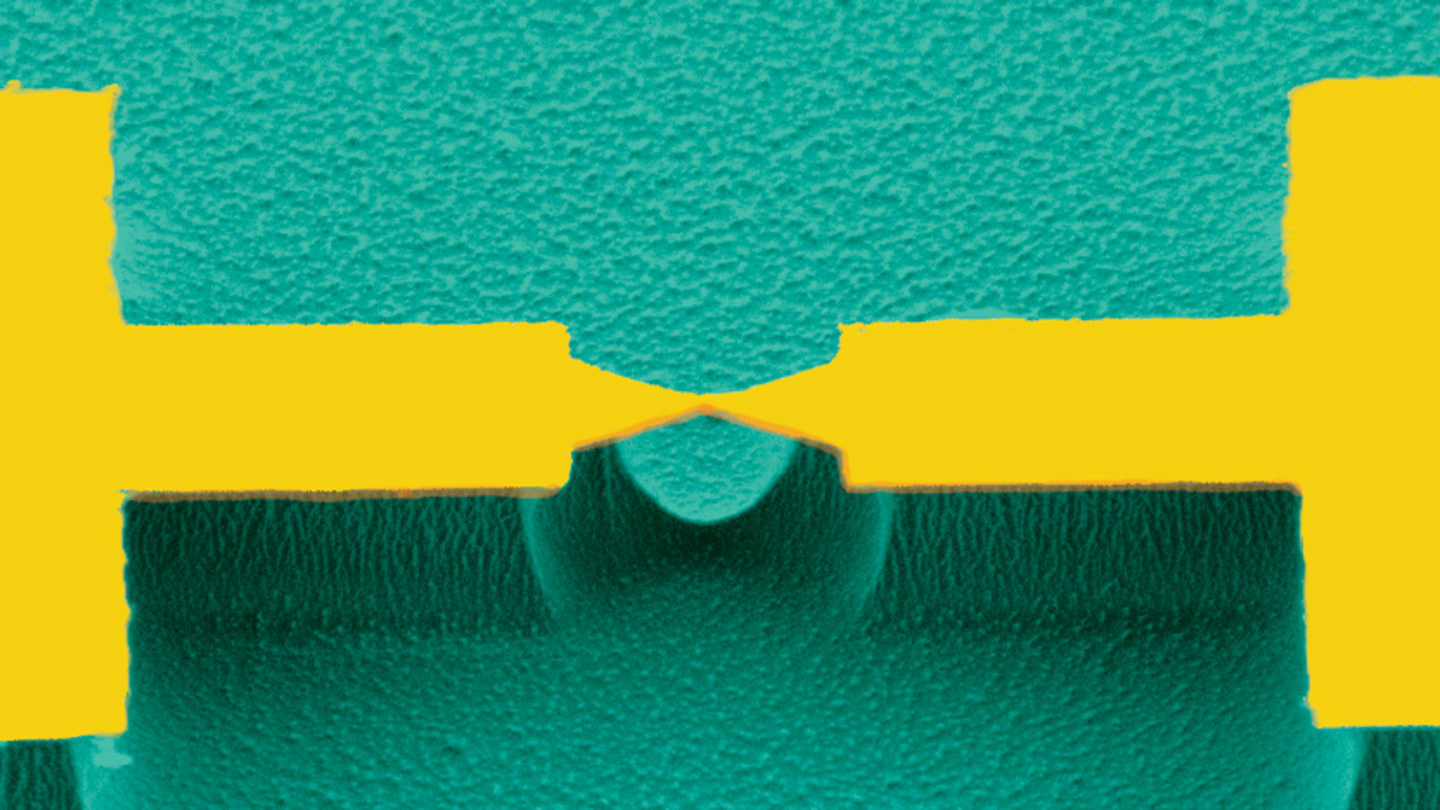

It is very difficult to create large nanostructures on curved or non-planar surfaces using existing modeling methods. In addition, current nanotechnology technologies such as electron beam lithography, optical lithography, interference lithography (IL), etc., can not meet all the application demands of industrial applications in terms of high resolution, high power, low cost. , Large area and olgoes on uneven and curved surface. Therefore, new high-volume nano-production technology is in dire need of exploitation and development to meet the tremendous needs of emerging markets. Nanoelectronic lithography is currently considered as a promising low-cost, high-power, high-resolution nano-pattern method, especially for the production of small-scale / large-scale nano-patterns and complex 3D structures. Top aspects of aspect ratio Given these outstanding benefits it has also created. The conversion of optical structures in combination with the construction of a large area becomes a more effective method in this field. In particular, nanoelectronic lithography has great potential for setting new benchmarks for making miniature, low-cost, lightweight optics that can be used in many applications.

The structure of nano-assemblers is one of the properties of nanoparticles in terms of surface to volume ratio of these materials. Using this property, powerful catalysts in nanometer dimensions can be produced. These nanocatalysts will greatly increase the efficiency of chemical reactions and will also significantly prevent the production of waste materials in the reactions. Nanoparticles in the production of other materials can increase their strength or reduce their weight. Increase their chemical and thermal resistance and change their reaction to light and other radiation. With the use of nanoparticles, the strength to weight ratio of composite materials will increase dramatically. Nanoassemblers are made of nanoparticles and the first effect of reducing the particle size is to increase the surface area. Increasing the surface to volume ratio of nanoparticles causes the atoms located on the surface to have a much greater effect on the physical properties of the particles than the atoms in the particle volume. Have. This property greatly increases the reactivity of nanoparticles. The structure of nano-assemblers is one of the properties of nanoparticles in terms of surface to volume ratio of these materials. Using this property, powerful catalysts in nanometer dimensions can be produced. These nanocatalysts will greatly increase the efficiency of chemical reactions and will also significantly prevent the production of waste materials in the reactions.

Conclusion :

The concept of nano -assemblies is summarized in all the information and code needed to produce an inventory similar to ours .

Researcher and author: Dr. ( Afshin Rashid)

PhD in Nano-Microelectronics